Agriculture Reference

In-Depth Information

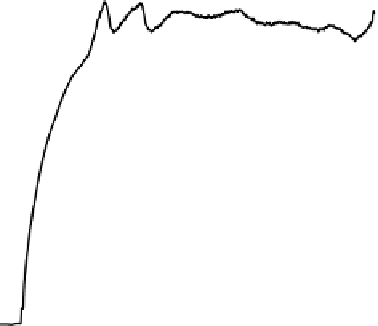

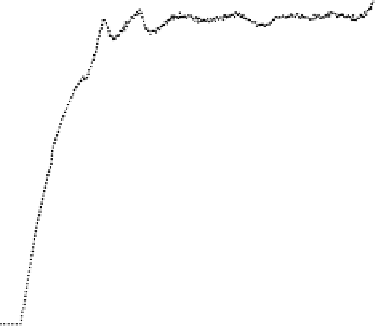

Subsequent inspection of the bed indicated a substantial volume of agglomerated sand

particles. Once the bed began to clinker, the fuel feed was switched off so that the bed

temperature decreased. The subsequent recovery in bed pressure as shown in the figure is

probably due to solidification of the sticky deposits and partial breakup of the weak brittle

bonds between sand particles by the air.

1000

400

900

350

800

300

700

250

600

500

200

400

Bed temperature

Freeboard temperature

Bed pressure

150

300

100

200

50

100

Raffinate on

0

0

0.00

0.50

1.00

1.50

2.00

2.50

Time (hr)

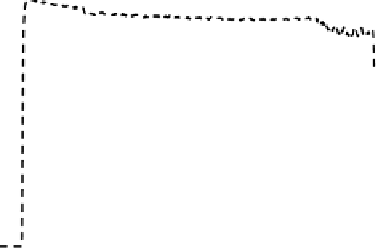

Figure 9. Bed behaviour during co-combustion of coal and raffinate.

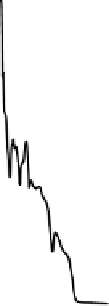

Table 17. Test conditions for Coal-Raffinate test

Coal flow for 81 min (kg/h)

2.8

Coal flow for 81 min (kW)

23.3

Coal flow for 7 min (kg/h)

3.2

Coal flow for 7 min (kW)

26.7

Raffinate flow (l/h)

2.88

Raffinate flow (kg/h), Density = 1320 kg/m

3

3.8

Coal to Raffinate feed ratio (kg/h)/(kg/h)

0.84

Coal (%)

45.7

Raffinate (%)

54.3

Coal only feed time (hrs)

0.9

(Coal + Raffinate) feed time (hrs)

0.57

Total coal feed time (hrs)

1.47

Total coal feed (kg)

4.22

Total reffinate feed (kg)

2.2

Coal to raffinate mass ratio (kg/kg)*

1.92

Sand to raffinate ratio (kg/kg)*

3.4

*Ratio of total material fed to the bed