Agriculture Reference

In-Depth Information

Table 15. Comparison of SO

2

emissions for Fuels and blends tested

SO

2

(mg/Nm

3

at 6% O

2

)

Fuel

C

a

/S

Mass

Molar

Coal

2500 - 2750

0.06

0.05

Coal-Pressed Pulp blend (50/50)

600 - 1200

0.61

0.49

Coal-Pressed Pulp blend (60/40)

1000 - 1500

0.44

0.35

Coal-Pressed pulp blend (70/30)

1800 - 2400

0.31

0.25

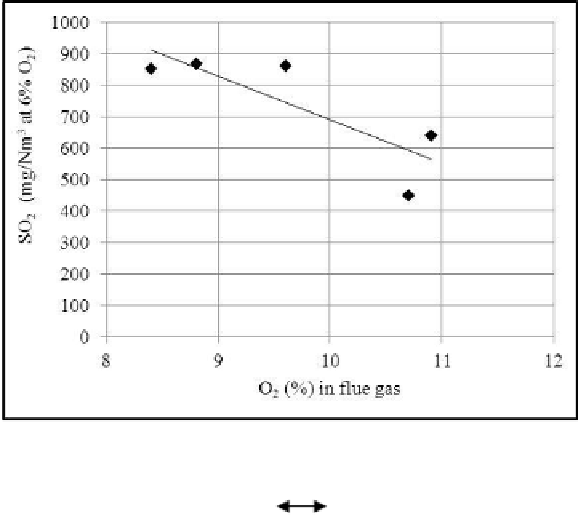

Figure 8. SO

2

vs. O

2

for 50/50 coal-pulp blend (11.8 kW).

2CaO + 2SO

2

+ O

2

2CaSO

4

(7)

The temperature at which maximum sulphur capture efficiency occurs is 800 °C - 900 °C

[Oka and Anthony, 2003] which is within fluidized bed operating temperature range. Change

in sulphation efficiency with variation in temperature in the vicinity of the optimum

temperature is not much. The optimum temperature for maximum SO

2

capture varies from

coal to coal [Fernandez et al. 1989] and from unit to unit. Leckner and Amand, (1987) have

shown that sulphation efficiency reduces significantly when temperature is below 780 °C or

above 960 °C.

Emissions of SO

2

reduce as biomass mass fraction is increased due to fuel sulphur

dilution. Because of low sulphur content of the biomass fuels SO

x

emissions decrease

depending upon the co-firing ratio and the sulphur content of the biomass. The emissions are

found to be lower when co-firing as compared to coal alone firing. An additional incremental

reduction beyond the amount anticipated on the basis of fuel sulphur content is possibly due

to the sulphur retention by alkali compounds in biomass ashes. During co-firing coal and pulp

blends SO

2

emissions were found to be decreased with increase in biomass fraction.

Thus the influence of volatiles on SO

2

emissions depends upon type of biomass fuel as

nature of volatiles varies from fuel to fuel. It is not possible to comment on the effect of

volatiles on SO

2

emissions due to influence of moisture on the emissions. Moreover, energy