Agriculture Reference

In-Depth Information

sugar making process, vinasse, raffinate and pressed sugar beet pulp (PP), using sugar beet as

raw material fall in the category of difficult biomass with low CV and high moisture content.

In order to understand the origin of these materials sugar making process is briefly described

hereunder.

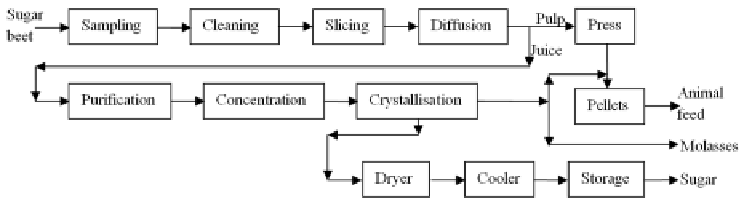

Sugar Beet is widely used to produce sugar. The simplified block diagram of the overall

process is shown in Figure 1. Sugar beet is processed initially to remove stone and soil and

the clean beet is then sliced into thin strips called cossettes. These are pumped to diffusers

where they are mixed with hot water to extract sugar juice. The raw juice is then separated

from the residual fibrous material which is mechanically pressed to partially remove

moisture. This so called pressed sugar beet pulp is dried in coal and oil fired driers before

being compressed into pellets which are sold in bulk as animal feed.

The raw juice is then progressively heated through complex heat recovery systems which

minimize the energy demand of the plant. Milk of lime and CO

2

are added to precipitate

calcium carbonate or chalk which removes the impurities in the raw juice. The extracted “thin

juice” passes through multiple effect evaporators which boil the water off and produce syrup

known as “thick juice”. Crystallisation of sugar takes place in pans which boil the thick juice

under vacuum. When the crystals are fully grown the blend of crystal sugar and syrup, known

as massecuite, is spun in centrifuges to separate the sugar from the syrup or “mother liquor”.

After the sugar crystals are washed, dried and cooled they are conveyed to storage silos.

The syrup is further processed to produce betaine, more sugar and raffinate for animal feed.

Raffinate which is also tested in this project is also known as “desugared beet molasses”. A

further biomass co-product also considered in this project is vinasse, a co-product from a

bioethanol process. Typical analyses of these sugar industry co-products are given in Table 1.

Figure 1.The sugar making process.

Table 1. Pressed pulp, Vinasse and Raffinate analysis [Akram, 2012]

Pressed pulp

Vinasse

Raffinate

Dry solids (%)

26 - 30

40 - 45

50

Total ash (%) db

6 - 8

22 - 25

36 - 44

Sugars (%) db

1.5 - 2.2

8.7

12 - 15

Volatiles solids (%) db

92 - 94

-

-

Sulphur (%) db

0.25

5

1

Nitrogen (%)d b

1.6

5

3.2

Phosphorus (%) db

0.1

0

0.16

Potassium (%) db

0.75

7

13

Sodium (%) db

0.1

2.5

3.6

Calcium (%) db

1.2

0.05

0.76