Agriculture Reference

In-Depth Information

In a scenario where ethanol from cane is exported to Europe, it would be transported

by a tanker ship. The requirement of bunker fuel for a 100 kt carrier, including the return

trip with ballast, is about r

ship

= 0

.

10 MJ

LHV

·

(t

OH

·

km)

−

1

[14]. Distance between São

Paulo port and Rotterdam in Netherlands - the main European port for fuel imports - is

about 10 000 km. The contribution from export by ship in LHV represents thus around

3.7% of ethanol LHV. In terms of energy balance, ethanol from cane would remain very

competitive.

4.7.2.

Gasoline production from crude oil

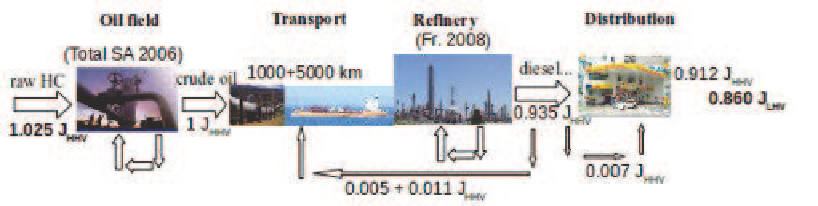

Figure 7. Energy flows through the main operations of the petroleum industry for 1 J of

crude oil high heat value HHV at the oil field output. Each operation consumes part of

its own input and/or part of refinery products. HC: hydrocarbons, Total SA: data from the

french company Total, Fr. 2008: average refinery in France in 2008. Source of values: [14].

Petroleum industry is nearly a self-reliant energy industry providing directly or in form

of refined products the requirements of its operations, as shown in Fig. 7. To produce 1 J of

gasoline LHV about 1.20 J of crude oil must be extracted, or 1 toe of gasoline requires 1.2

toe of crude oil.

On the other hand, quantity of crude oil in reservoir rocks which allow this efficient

extraction is limited. As a result, its global production will decline from present level,

or even is already in decline. Marginal but growing productions from tar sands, very tight

rocks such as in USA, watered reservoirs without natural pressure support... present a much

larger energy requirement at the field, which, in extreme cases, can be even higher than the

output (see an example at the end of Chap. 3 in [9]). This situation has been financially

possible as crude price has increased while prices of electricity, and gas in some situations,

have remained more stable. In addition, consumption at the refinery can be as high as 12%

of its input HHV in order to meet environmental regulations and increased demand for

transportation fuels requiring additional and energy consuming processes [14].

Industries of ethanol from sugar plants, in particular sugar cane, can benefit from this

development. However, due to their limited cultivation areas and the demand for sugar,

neither beet or cane can substitute for fossil oil in large scale.

Beet based ethanol industry can divert a part of its production to be also self-reliant.

From the previous analysis, 0.66 J of energy LHV must be consumed to produce 1 J of

ethanol. Consequently, if ethanol must provide all the requirements of its industry, 1 toe

of energy net production will necessitate the gross production of 2.94 toe of ethanol, the

processing of 57 t

A

·

and a surface of 0.76 ha per year. All the area dedicated to beet culture