Agriculture Reference

In-Depth Information

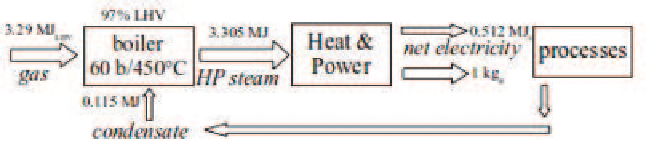

Figure 6. Energy flow diagram of a combined heat and power generator providing electricity

and 1 kg of steam to factory processes. It operates with superheated steam at 60 bars and

450

◦

C. Flows represent LHV of gas and enthalpy of water (with 0 kJ for liquid water at

0

◦

C).

of gas to provide 305

kg

st

·

t

−

1

A

of steam and 157

MJ

e

·

t

−

A

of electricity.

An additional generator operating with the same superheated steam but in power mode

alone could supply the remaining electricity requirement. Assuming a turbine expanding

steam close to iso-entropic condition - at 80% - and a condenser working at 20

◦

C, electricity

yield is 24.5% net/LHV.

Total energy requirement at the factory supposedly supplied by gas - or ethanol on a

LHV basis - amounts to 1.30

GJ

LHV

·

t

−

1

A

. Deducting the gain from pulp the net amount is

1.20

GJ

LHV

·

t

−

A

or about 56% of the LHV of the produced ethanol.

In terms of primary energy consumption (mostly gas in our model), we obtain a net

requirement of 1.45

GJ

tot

·

t

−

1

or about 67% of production of ethanol LHV.

A

4.7.

Synthesis about Consumption Efficiency. Comparison with those

for Cane based Ethanol and Gasoline Productions

From the farm to the fuel dispenser requirements to produce ethanol from beet are equiv-

alent to 66% of the ethanol energy, on a LHV basis, or close to 80% on a primary energy

basis (mostly gas and oil).

4.7.1.

Ethanol production from cane

Operations to produce ethanol from cane are similar, or even identical, to those in the beet

case.

All operations at the farm are assumed mechanized and burning practice has been

phased out, which should be the practice after 2020 [25]. Total diesel consumption amounts

to about 230 l

·

(ha

·

y)

−

1

[25], or 195 l

·

(ha

·

y)

−

1

by including the fallow area in the 6 year

cycle of plant culture. Total associated consumption amounts to 8.4

GJ

tot

·

(ha

·

y)

−

1

.

As cane is a perennial plant, it minimizes losses and profits from organic mineralization.

Leaves left in the field during harvest, as well as process residues - stillage and filter cake

mud - restored to soil, are assumed to bring back their N content. Nevertheless, synthetic

N fertilizer must at least offset the loss of bagasse N due to its burning, which amounts

to

0

.

93

±

0

.

15 kg

N

·

t

−

1

(N content of bagasse dry matter is

6

±

1 kg

N

·

t

−

1

DM

, according

to Hassuani et al. [32], with 150

kg

DM

·

t

−

A

of DM in cane). By including about 20% of

losses, we obtain an input of

1

.

15

±

0

.

15 kg

N

·

t

−

A

equivalent to

90

±

10 kg

N

·

(ha

·

y)

−

1

,

which results in 3.70

GJ

tot

·

(ha

·

y)

−

1

of energy consumption for fertilizer manufacture.

A