Agriculture Reference

In-Depth Information

structure is more porous (Filipović, 2005), so the internal mass transfer resistance is smaller.

The reason for this phenomenon lies in changing of the fibers structure during chemical

treatment, when the esterification of pectin present in them and increased water binding

(Feeney et al. 1989), therefore reduced water viscosity with increasing rehydration

temperature leads to higher rehydration initial rates compared to untreated fibers.

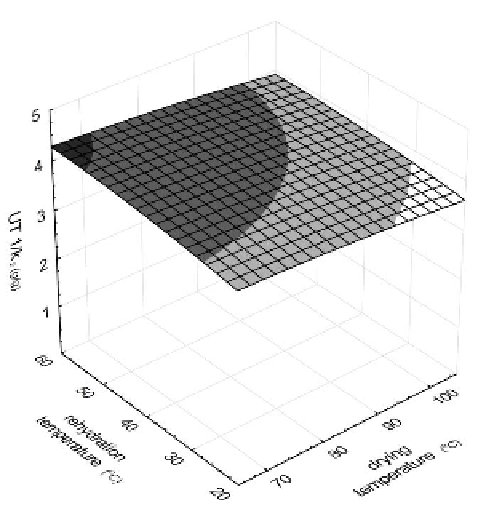

The effect of drying temperature on the rehydration initial rate of treated sugar beet pulp

is more pronounced in relation to its effect in untreated fibers (Figure 1). The reason for this

is already mentioned changes in the pulp structure with the fact that increased porosity results

in lower internal resistance. In fact, even at low rehydration temperatures increase in drying

temperature result in the reduction of the rehydration initial rate compared to untreated fibers

where the effect of drying temperature on the initial rate is limited to higher rehydration

temperatures. The values of the rehydration initial rate for treated fibers are roughly equal to

those that are obtained for untreated fibers which, however, suggest that in this case the

dominant resistance to mass transfer is external.

The equilibrium moisture content of the treated dietary fiber is significantly higher than

the moisture content of the untreated fiber (Figure 4). In contrast to the untreated fibers in

treated one, the effect of drying temperature is more significant factor in relation to the

equilibrium moisture content. The reason for this behavior is in the change of fiber structure,

by increasing the drying temperature degradation of the porous properties of the treated fibers

is greater and it reduces the equilibrium moisture content. For that reason it is necessary to

choose the correct drying temperature so that decrease in equilibrium moisture content should

be kept as small as possible, while at the same taking into account that the drying process

does not last too long at low temperatures.

Figure 2. Effects of rehydration temperature and convective drying temperature on equilibrium

moisture content rate of untreated sugar beet pulp.