Agriculture Reference

In-Depth Information

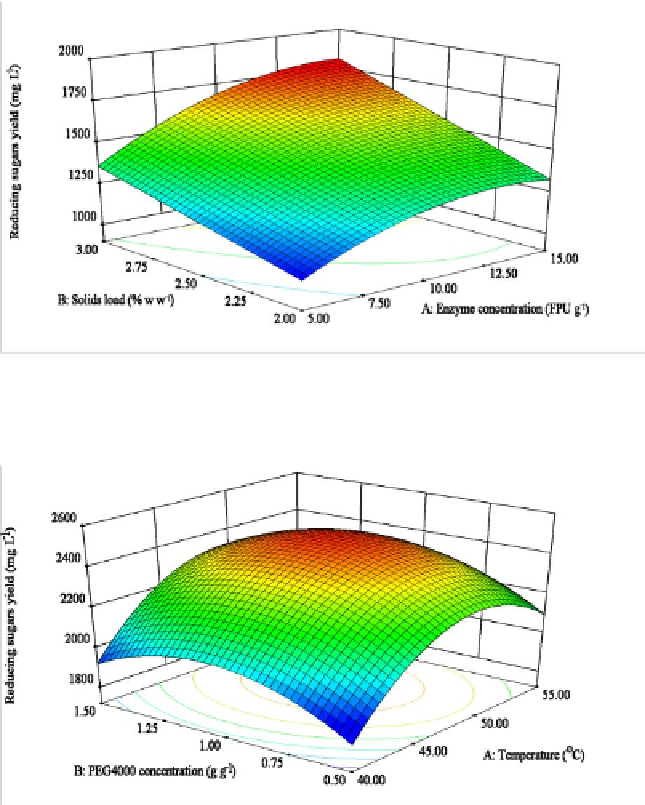

Applied acidic pretreatment proved to be successful in preparing sugar beet shreds for

cellulases action providing increase in hydrolysis yield 1.65 times in comparison to untreated

ones (Figure 2). Statistical analysis showed significance of the models for reducing sugars

yield as response in which PEG molecular weight/PEG concentration, enzyme

concentration/solids load and temperature/PEG 4000 concentration were independent

variables. The highest reducing sugars concentration was achieved under next conditions - 1 g

PEG 4000/g substrate, 47.5

o

C, enzyme concentration 10 FPU/g and 3% (w/w) solids load,

representing 1.6-fold increase in hydrolysis yield in comparison to the one obtained at lower

temperature and solids load and in absence of PEG (Figures 3 and 4). Addition of PEG opens

the possibility to reduce the both consumption of enzyme and time of hydrolysis without

decreasing in yield of reducing sugars. In addition, it was indicated that by addition of

polyethylene glycol 4000 at 1 g/g substrate, enzyme concentration and hydrolysis time could

be reduced by approximately two thirds and one third, respectively, without loss in sugars

yield [52]

.

Figure 3. Response surface of reducing sugars yield released by enzymatic hydrolysis of pretreated

sugar beet shreds as function of enzyme concentration and solids load; temperature 40

o

C; hydrolysis

time 48 h [52].

Figure 4. Response surface of reducing sugars yield released by enzymatic hydrolysis of pretreated

sugar beet shreds as function of temperature and PEG 4000 concentration; enzyme concentration 10

FPU/g, solids load 3% (w/w), hydrolysis time 48 h [52].