Geoscience Reference

In-Depth Information

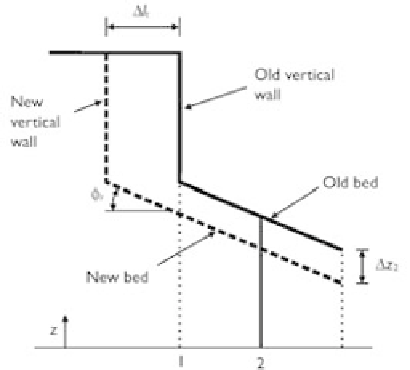

Figure 7.17

Headcut migration due to toe scour.

p

0.4

c

−

ρ

b

/ρ

2

; and

m

−

3

). At each time step

M

=

/(

1

)

ρ

s

is the soil density (kg

·

t

,

s

Eq. (7.71) gives the headwall retreat length

l

s

due to hydraulic shear.

The sediment transport in the plunge pool, which is highly affected by the rapidly-

varied jet impinging flow, is simulated using the 3-D model introduced in Section 7.3

with the sediment transport capacity determined using Eqs. (3.70) and (3.95) with the

corrections described in Eqs. (7.63) and (7.68). From this calculation, the bed change

z

2

at the center of the first control volume near the toe of headwall surface at the

time step

t

can be obtained, and then, the headcut retreat length due to this toe scour

is given as

l

t

=

z

2

/

tan

φ

r

, as shown in Fig. 7.17. Here,

φ

r

is the repose angle of

sediment. The actual headcut migration length is the larger of

l

t

.

The time-averagedmodel described above simulates the headcut migration caused by

the headwall surficial erosion and toe erosion. These two erosion modes are the main

factors of headcut migration, as they induce the mass failure and wash out the wasted

sediment debris. Therefore, this time-averaged model can acquire the main features of

headcut migration.

The headcut boundary propagates upstream and expands sideward. A moving grid

technique is implemented to capture this moving boundary in the horizontal directions,

combined with the original one to track the water surface change and bed deformation

in the vertical direction. At each time step or iteration step, the computational grid is

adjusted after the calculations of water level, bed deformation, and headcut migration.

The established headcut migration model was tested by Wu and Wang (2005) using

the experiments of Bennett

et al

. (1997). The experiments were carried out in a flume

5.5m long. The test part was a cavity 2m long and 0.165m wide, filled with 0.25m

deep soil. The bed slope of the flume was 1%. The used soil was the parent material

of the Ruston silt loam after being crushed and air-dried and consisted of 20.0% clay,

2.9% silt, and 77.1% sand. A preformed 0.025m high headcut was constructed at

the downstream end of the cavity. Application of simulated rain produced a surface

seal layer to negate any detachment of the soil material by the subsequent overland

l

s

and