Chemistry Reference

In-Depth Information

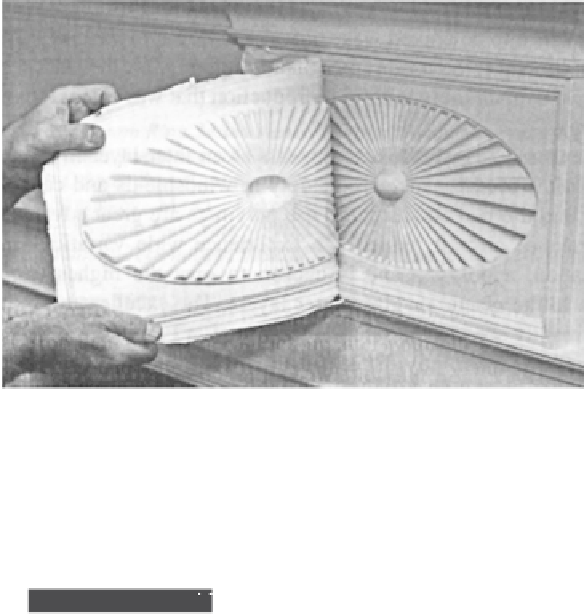

Figure 10.6:

A polysiloxane Room-Temperature Vulcanizate (RTV) being used to make a mold of an

intricately carved surface. The photograph was provided by the Dow Corning Corporation

of Midland, MI.

PDMS

PDMS

Si

PDMS

PDMS

Au

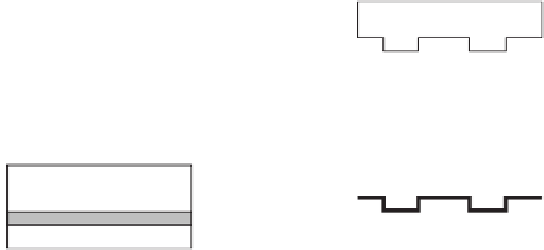

Figure 10.7:

Steps in soft lithography. The PDMS in the beginning sketch is first cross linked, then

removed, and then coated with a thiol that transfers the original pattern to a gold layer.

master), (ii) ease of cross linking at ambient temperatures (to make the

features of the stamp permanent), (iii) superb elasticity and robustness

(for removing the PDMS stamp and using it in microcontact printing),

and (iv) excellent stability (for long-term storage of patterns).

Mention should be made of the use of polysiloxanes in the area of mi-

crofluidics.

22,26

Devices of this type have channels or capillaries with di-

mensions 10-10,000 µm, and their preparation is relatively straightforward

with PDMS, using the soft-lithography techniques just described to make

the required molds.