Chemistry Reference

In-Depth Information

swelling measurements obtained on unfilled and filled PDMS elastomers

to estimate the degree of adhesion between elastomer and filler parti-

cles.

117-119

The results differ greatly from those for nonadhering fillers, in-

dicating good bonding between the two phases. Resistance to separation

from the surface in such swelling tests does not contradict the chains

having considerable mobility

along

the surface.

In situ-generated silica fillers improve creep resistance and compress-

ion set in cyclic deformation.

120

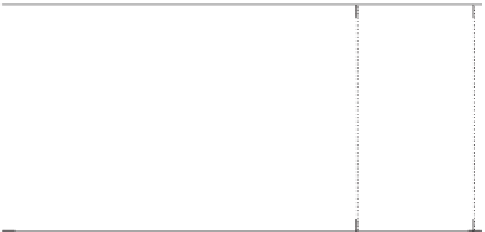

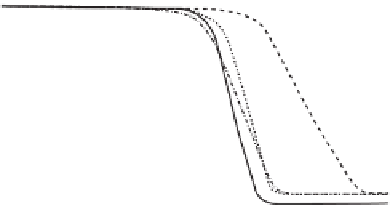

The filled samples show very little com-

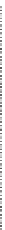

pression set (figure 9.7). Thermal stability also improves as reflected by

higher decomposition temperatures. (figure 9.8)

121

A possible mechanism

3.0

12.4%

2.5

2.0

19.4%

1.5

1.0

0%

0.5

0.0

0

20

40

60

80

Time, hours

Figure 9.7:

Effect of cyclic stress on unfilled PDMS and PDMS elastomers filled with in situ precipi-

tated silica: (∆) unfilled, (⚫) 12.0 wt % silica, (O) 19.4 wt % silica.

120

100

80

Comm-AE

60

40

A

Comm-MO

20

U

0

100

200

300

400

500

600

700

800

T (

C)

Figure 9.8:

Comparison of thermogravometric plots for PDMS networks that were unfilled (U), or

contained either in situ precipitated silica (A) or commercial fume silica (COMM-MO and

COMM-AE).

121

The heating was under nitrogen.