Chemistry Reference

In-Depth Information

M

S

/

M

L

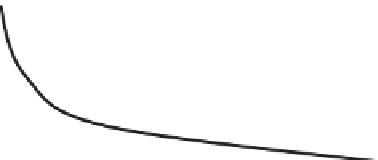

Fi g u re 7. 24:

Maximum tensile strengths in tearing for bimodal elastomers as a function of the ratio of

the molecular weights of the short and long chains.

important to establish the molecular weight at which this decrease occurs

for a variety of deformations and a number of different elastomers.

Some Rheovibron viscoelasticity results have been reported for bi-

modal PDMS networks.

270

Measurements are first carried out on uni-

modal networks consisting of the chains used in combination in the

bimodal networks. One of the important observations was the depend-

ence of crystallinity on the network chain-length distribution.

Some measurements have been made on the permanent set of PDMS

networks in compressive cyclic deformation (figure 7.25).

271

here ap-

peared to be less permanent set or creep in the case of the bimodal elasto-

mers, consistent in a general way with some early results for polyurethane

elastomers.

272

Specifically, cyclic elongation measurements on unimodal

and bimodal networks indicated that the bimodal ones survived many

more cycles before fatigue failure. The number of cycles to failure is ap-

proximately an order of magnitude higher for a bimodal network, at the

same modulus (Mod10) at 10% deformation

96

Also viscoelastic effects in

bimodal networks are not simple averages of contributions from the short

and long chains.

270,

273

7.3.2.6 Results on Nonmechanical Properties

Birefringence can be used to characterize non-Gaussian behavior in PDMS

bimodal elastomers.

96,

274 -

278

A large decrease the stress-optical coefficient

(ratio of birefringence to stress) was observed over a relatively small range

in elongation,

78

presumably due to limited extensibility of the short chains.