Image Processing Reference

In-Depth Information

4. Protocols used in the different testing experiments

Two types of experiments (I and II) have been designed with the purpose of evaluating and

comparing the three trace combination methods presented in the previous section. The

comparison will be performed over the same set of ultrasonic traces for the three cases. The

type-I experiments are based on simulated noisy ultrasonic traces and those of type-II use

experimentally acquired echo-traces. The protocols used in these experiments are an

extension of those we have planned in references (Rodríguez et al 2004a, Rodríguez 2003,

Rodríguez et al 2004b).

4.1 Experiments type-I based on simulated noisy traces

Type-I experiments were carried out with simulated signal registers. They provide adequate

calculation results to confirm the accuracy of the expressions estimated from the theoretical

models of the processing techniques proposed in the equations (3), (5) and (8) to predict the

distinct SNRs (

SNR

2Dtime

,

SNR

2DTFlinear

and

SNR

2DWVT

). So, those expressions could be

validated for an ample range of values in

SNR

ini

with perfectly controlled characteristics in

echo-signals and their associated grain noises. Some results, in a similar context, using these

same rather simple simulated registers, have been compared in a previous work (Rodríguez

et al 2004a) with the obtained results when a more accurate ultrasonic trace generator was

used. A very close agreement between them was observed, which confirms the suitability of

these registers to evaluate those expressions.

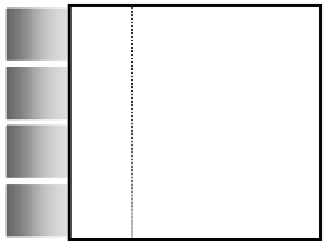

The testing case proposed to attain this objective is the location of a punctual reflector into a

rectangular parallelepiped from 2 external surfaces, perpendicular between them, and using

4 transducers by surface. The general scheme of these experiments, with 4 horizontal (H1,

H2, H3, H4) and 4 vertical (V1, V2, V3, V4) transducers is depicted in the Figure 4.

Transducers H3 and V2 receive echoes from the reflector whereas the other transducers (H1,

H2, H4, V1, V3 and V4) only receive grain noise. To assure compatibility of experiments

type-I with experiments type-II, ultrasonic propagation in a piece of 24x24 mm has been

simulated assuming for calculations a propagation velocity 2670 m/s very close to that

corresponding to methacrylate material. The sampling frequency was 128 MHz.

H4

H3

H2

flaw

H1

V1

V2

V3

V4

Fig. 4. Geometry of the inspection case planned to evaluate the different combination

methods: detection of a single-flaw in a 2D arrangement with 16 elemental-cells.