Environmental Engineering Reference

In-Depth Information

Step 4

: After the modification of the network, the model simulation runs again. If one or more

virtual reservoirs have received more water than the original demand of the corresponding

node, those virtual reservoirs are removed from the network and the original nodal demands

are restored. For example, the demand of virtual reservoir 7 (86.09 l/s) has exceed the

original demand of node 2 (20.10 l/s) and this reservoir can be removed from the network in

the next iteration. The reservoir in node 4 receives 34.23 l/s, which is less than the original

demand of 40.20 l/s. For that reason, this reservoir stays attached to node 4 in the next

iteration, as is the case with those in nodes 3, 5 and 6.

Step 5

: With the original demand of node 2 restored, the simulation is run again. In nodes

where the reservoirs receive less water than the original nodal demand, their supply shows

the degree of the demand reduction. The iterative process continues until there is no change

in the setup of the virtual reservoirs and ordinary nodes in two consecutive iterations. In this

example, the total available demand stabilises at 93.38 l/s. The overall available demand

fraction resulting from the burst of pipe 6 (ADF

6

) is therefore 61.94% (93.38/150.75). The

original demand of nodes 2, 3, and 4 is fully satisfied, whilst the demand of node 5 will be

partially satisfied (ADF

5

= 9.72 %). Node 6 will receive no water as a result of the pipe burst

(ADF

6

= 0 %).

Step 6

: In the final step, the actual nodal pressures are calculated based on the true demand.

The above procedure is rather complex if it is to be applied for extended period simulations

and any larger network, where each pipe is to be failed in the availability/ reliability analysis.

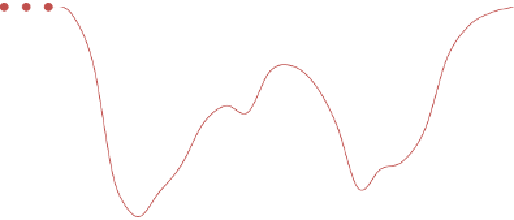

Using the programme for ADF calculation, developed by Yoo et al. (2005), the results of the

test network calculated for the applied demand pattern are shown in Figure 2.6, with the

average availability factor of 0.8789, higher than the average reliability factor of 0.7742. This

is normal knowing that the availability assumes possibility of repair of the failed system

component. Also logical is that the higher demand in the system inflicts the lower values of

the availability and reliability factors, during particular hours of the day.

Applying the same procedure for any other demand scenario, makes possible to compile the

reliability and availability curves for 24-hour period, as is shown in Figure 2.6.

1.00

Availability - A(t)

0.90

0.80

0.70

Reliability - R(t)

0.60

0.50

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Time - t (hours)

Figure 2.6

Hydraulic reliability and availability for network from Figure 2.5 (Yoo et al., 2005)

Search WWH ::

Custom Search