Environmental Engineering Reference

In-Depth Information

of the system components. Evaluating the pipe itself, it could be considered as a non-

repairable component if it has to be replaced by a new one, while in the evaluation of the pipe

as a component of the water distribution system, it is repairable i.e. available component.

The availability of a component can also be expressed as a percentage of the time during

which the component is in operational state. The remaining is the time when the component

is not functional, most frequently due to a failure or some maintenance. There are two basic

categories of maintenance events:

-

Corrective maintenance

, which includes repair after a breakdown or unscheduled

maintenance resulting from the equipment failure. This additional information should be

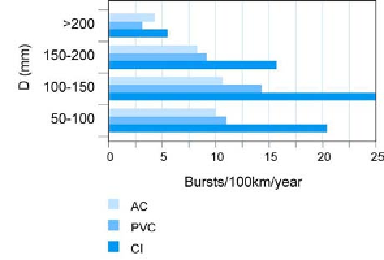

available from the maintenance records, depending on the pipe material and its condition;

the records can be summarised in the form of a diagram as shown in Figure 2.1 (source:

Vreeburg and van den Hoven, 1994).

-

Preventive maintenance

, which includes regular activities to prevent breakdowns before

they occur.

Figure 2.1

Pipe bursts frequency; example from The Netherlands (Vreeburg and van den Hoven, 1994)

On annual basis, the component availability can be calculated as:

8760

−

CMT

−

PMT

A

=

2.2

8760

where

A

stands for component availability,

CMT

is annual corrective maintenance time in

hours, and

PMT

is annual preventive maintenance time in hours.

1

0.9

0.8

0.7

Availability - A(t)

0.6

0.5

0.4

0.3

0.2

Reliability - R(t)

0.1

0

0

10

20

30

40

50

60

Time - t (years)

Figure 2.2

Reliability and availability trends (adapted from Tung, 1996)

Search WWH ::

Custom Search