Environmental Engineering Reference

In-Depth Information

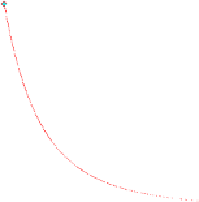

0.01 m/km, will require different diameter if the pipe length changes; this can be seen in

Table 7.14 and Figure 7.17.

Table 7.13/Figure 7.16

Correlation b

etween optimal diameter and pipe volume, L = 1000 m, S = 0.01

V (m

3

)

Q (l/s)

D (mm)

10

113

10.029

20

147

16.972

30

171

22.966

40

191

28.652

90

50

207

33.654

R² = 1

80

60

222

38.708

70

70

236

43.744

60

80

248

48.305

50

90

259

52.685

40

100

270

57.256

110

280

61.575

30

120

289

65.597

20

130

298

69.746

10

140

306

73.542

0

0

20

40

60

80

100

120

140

160

150

315

77.931

Qpipe (l/s)

Table 7.14/Figure 7.17

Correlation between optimal diameter and pipe volume, Q = 100 l/s, h

f

= 10 mwc

L(m) S(-) D (mm) V (m

3

) v (m/s)

100 0.100

172

2.324

4.31

200 0.050

197

6.096

3.29

300 0.033

213 10.690

2.81

400 0.025

225 15.904

2.51

120

500 0.020

235 21.687

2.30

600 0.017

244 28.056

2.14

100

700 0.014

252 34.913

2.01

80

800 0.013

258 41.823

1.91

900 0.011

264 49.265

1.82

60

1000 0.010

270 57.256

1.75

1100 0.009

275 65.335

1.69

40

1200 0.008

279 73.363

1.63

20

1300 0.008

284 82.351

1.58

R² = 1

1400 0.007

288 91.202

1.53

0

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

1500 0.007

292 100.449

1.49

vpipe (m/s)

Hence, the pipe lengths also influence the correlation between the flows and volumes, next to

the diameters. Nevertheless, common engineering practice deals with some design principles

in which not every combination of parameters would be applied. For instance, the velocities

much above 1 m/s would be causing too high energy losses/consumption. Equally, the

hydraulic gradients much above 0.01 mean increased operational costs. Furthermore, neither

very long pipes of small diameter nor short pipes of large diameter would be common in

water distribution networks. The issue is therefore how good is the correlation between the

parameters of commonly designed pipes.

Search WWH ::

Custom Search