Environmental Engineering Reference

In-Depth Information

Drawing the conclusion about the reliability of the Amsterdam North network, based on the

outlook of the corresponding HRD, the network is generally over designed and could

function properly with smaller diameters for majority of the pipes. To increase the reliability

on the other hand, one should concentrate on the couple of major pipes, alone. Seven of these

are the main reason for 24 % of the demand loss, which is the consequence of the worst pipe

failure scenario. How far this should be done, is a decision for the water company.

The seven most critical pipes identified by the developed network diagnostics software are (D

in mm/L in m): 15003 (800/18), 15004 (800/20), 15005 (800/19), 15006 (762/35), 15007

(769/320), 17824 (800/9) and 17825 (800/8). To demonstrate the implications of the network

renovation on the improvement of the three indices, a pipe of 800 mm diameter and 430 m

length has been connected between the node 14226, which is the first one (upstream) in the

series of seven pipes, and 12444 being the last one (downstream) and the major discharge

node of Q = 112.14 l/s. In this case, a parallel pipe has been added to the network

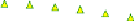

strengthening one of its branches towards the area of high demand. The results in Figure 5.28

show the improvement, with following values in the final simulation run, nr. 15: I

r

= 0.288, I

n

= 0.264, NBI = 0.500, ADF

avg

= 0.9941 and ADF

min

= 0.777.

1

0.9

0.8

0.7

Ir

In

NBI

ADFavg

ADFmin

0.6

0.5

0.4

0.3

0.2

0.1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Figure 5.28

Implication of network renovation on I

r

, I

n

and NBI (total demand incr. 73%)

While the values of

I

r

and

I

n

do not change significantly compared to the situation in Figure

5.25, the effect of having parallel pipe on a branch leading to the major demand node is

clearly captured in higher value of NBI in the first couple of simulations, being indirectly

influenced by much higher value of

ADF

min

compared to the original situation with single

branch. This effect is obviously diminished as the demand is growing so that the NBI value

towards the final simulation showing the demand increase of 73 % is less different than in the

first case.

5.9

CONCLUSIONS

The research presented in this chapter aims at alternative way of expressing the reliability

index being derived from a diagram showing the correlation between the pipe flows under the

regular supply conditions and the loss of demand caused by their failure. The proposed

diagram, called the hydraulic reliability diagram (HRD), considers the reliability of zero in

Search WWH ::

Custom Search