Biomedical Engineering Reference

In-Depth Information

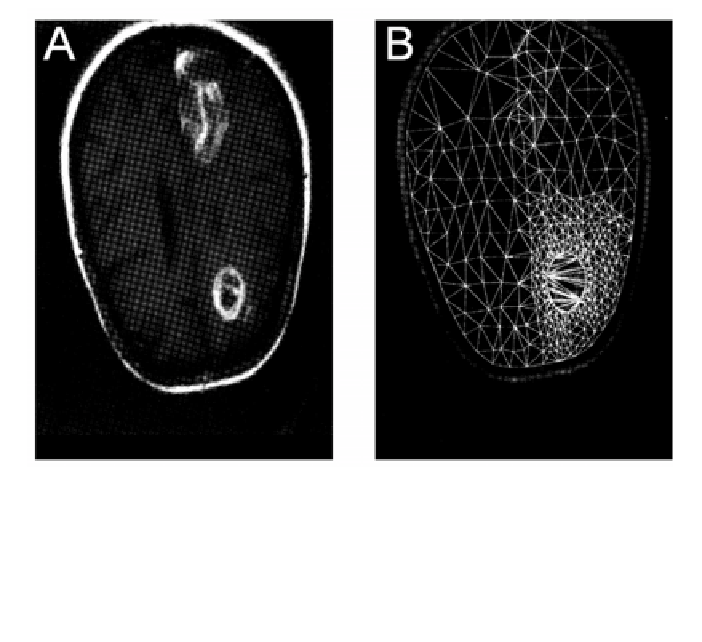

Figure 2

. (

A

) Initial MRI scan of a patient with a brain tumor. (

B

) Two-dimensional finite-

element mesh constructed from the image in (A). Data from Wasserman et al. (76), reproduced

with permission.

While simplified models based on displacement of rigid or incompressible tissue

elements might be considered (75), FEM provides the obvious approach to deal-

ing in a more principled way with the inelastic distortions and possibly compres-

sion that might be expected to occur during normal or cancerous growth in the

nervous system. An early example of a two-dimensional FEM tumor model is

shown in Figure 2 (76). FEM can be applied at any desired spatial scale from

some upper limit where the mesh elements would grossly violate the assumption

of internal homogeneity right down to the subcellular level. Thus, development

of software for this application, if properly designed, is an activity that might not

have to be iterated as each new generation of models at successively smaller

scales comes online.

As with identification of tissue types from images, automated mesh genera-

tion is a significant requirement for FEM, if for no other reason than that mesh-

ing is entirely too tedious to perform manually in a three-dimensional structure

of any useful size. As is the case with tissue type segmentation, meshing rou-

tines are available, even in the commercial FEM packages, but software will

need to be developed to couple the results of tissue segmentation into the selec-

tion of mesh nodes and the assignment of material properties to the mesh ele-