Environmental Engineering Reference

In-Depth Information

0,40

BTSE 5%, 2min

BTSE 5%, 5 min

BTSE 5%, 10 min

0,35

0,30

3

0,25

2

0,20

1

0,15

0,10

0,05

0,00

1800

1600

1400

1200

1000

800

Wavenumber (cm

-1

)

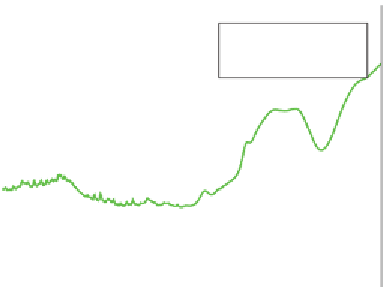

Figure 2.18

FTIR spectra of bis-3-(triethoxysilyl) ethane i lm on TSA anodized AA 2024.

1

- BTSE 5%, 2 min conversion, drying at 100

°

C, 5 min;

2

- BTSE 5%, 5 min conversion,

drying at 100

°

C, 5 min;

3

- PSS 5%, 10 min conversion, drying at 100

°

C, 5 min.

to the layer density). In the case of conversion with BTSE and PSS 2%,

it can be noticed that the treatment time has nearly no inl uence on the

-Si-O-Si- peak intensity when compared with BTSE and PSS 5%, where

from the spectra the peak intensity has an increase proportional with the

conversion time.

2.6 Conclusions

It has been demonstrated that the silane mixture of bis-amino silane/bis-sul-

fur silane shows superior corrosion resistance properties when applied on

the aluminium surface compared to a mixture of bis-amino silane/VTAS

or only BTSE and bis-sulfur silane, respectively. A small volume of bis-

amino silanes is sui cient to generate hydrophilic properties on the sur-

face and to support the formation of a homogenous surface i lm on the

anodized AA 2024 sample. On the other hand, a large portion of bis-sulfur

silane enhances the hydrophobicity of the mixture i lm, being the basis for

good protective performance properties of the mixture when applied on

the AA2024 surface. h e mixture of bis-sulfur silane with bis-amino silane

in a ratio of 3:1 showed the highest corrosion resistance on AA 2024-T3.

h e improvement for this mixture is achieved by selectively overcoming

the major drawbacks of the two individual silanes. h e bis-sulfur/bis-amino

mixture enhances the corrosion resistance of aluminium alloys due to the

Search WWH ::

Custom Search