Environmental Engineering Reference

In-Depth Information

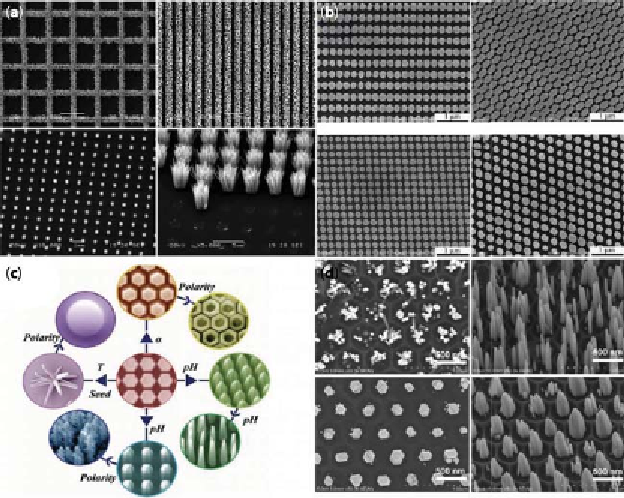

Figure 16.2

(a) E-beam lightraphically patterned ZnO nanorod [76]. (b) Nanoscale

two-dimensional patterns of ZnO nanorods using laser interference lithography [74].

(c) polymer-templated hydrothermal growth of patterned ZnO nanorods and various

morphologies [80]. (d) Sot chemical templated (polystyrene sphere and TiO2 layer)

control growth of ZnO nanowires [75].

needle-like, tubular, tree-like, and spherical shapes are obtained by con-

trolling the growth conditions. Figure 16.2c represents various morpholo-

gies of ZnO nanostructures which utilized various growth conditions and

structural polarity [74]. A direct patterning of ZnO nanoparticle (NP)

seeds via microcontact printing demonstrated excellent spatial control

over nanowire growth in a large area, which can also be performed on

l exible substrates to be utilized in l exible electronic devices [79]. h is

kind of printing needs master stamps with dei ned structures, the con-

centration and viscosity of ink (seed solution) plays an important role

on pattern quality [81]. h ough top-down approaches to patterning have

shown superb control over patterns, these processes are very time con-

suming and require high cost tools and excellent operating skills. Hence,

the sot chemical-based self-assembled monolayer approach is becoming

quite attractive for large-scale and low-cost patterning. Monolayer of PS

Search WWH ::

Custom Search