Environmental Engineering Reference

In-Depth Information

3.5

3.0

0%

1%

2%

4%

8%

10%

3.0

2.5

2.5

2.0

2.0

1.5

1.5

1.0

1.0

0.5

0.5

0.0

0.0

0%

1%

2%

Boron nitride wt%

5%

8%

10%

0.0

0.5

1.0

1.5

2.0

Pressure, psi

(

a

)

(

b

)

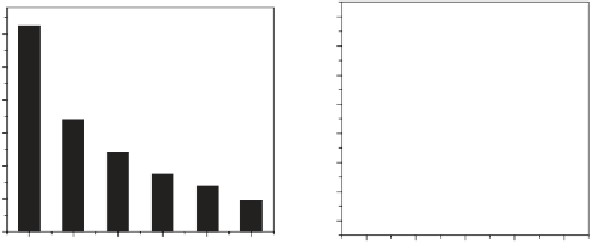

Figure 13.7

(a) h e oxygen permeability of cellulose/BN nanobiocomposites with

various loading of BN at constant pressure of 2 psi, and (b) the oxygen permeability of

cellulose/BN nanobiocomposites with various loading of BN at dif erence pressure [24].

13.5 Conclusion

Bionanocomposites were prepared by solution technique with dispersion

of reinforced nanomaterials with biopolymer matrix. h is technology

was developed to improve barrier performance to gases such as oxygen.

It also enhances the barrier performance to ultraviolet rays, as well as

adding strength, stif ness, dimensional stability, and heat resistance. New

plastics created with this technology demonstrate an increased shelf life

and are less likely to shatter. Once perfected, these plastics will of er these

improved characteristics at competitive prices. It will also make them

attractive for use in food and beverage packaging and pharmaceutical

packaging applications.

References

1.

A. Samir, F. Alloin, J.Y. Sanchez, A. Dufresne, Cellulose nanocrystals rein-

forced poly(oxyethylene),

Polymer

, Vol. 45, pp. 4149-4157, 2004.

2.

K.M. Dean, M.D. Do, E. Petinakis, L. Yu, Key interactions in biodegradable

thermoplastic starch/poly(vinyl alcohol)/montmorillonite micro- and nano-

composite,

Comp. Sci. Tech.

, Vol. 68, No. 6, pp. 1453-1462, 2008.

3.

J.K. Pandey, A.P. Kumar, M. Misra, A.K. Mohanty, L.T. Drzal, R.P. Singh,

Recent advances in biodegradable nanocomposites,

J. Nanosci. Nanotech.

,

Vol. 5, No. 4, pp. 497-525, 2005.

Search WWH ::

Custom Search