Environmental Engineering Reference

In-Depth Information

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

2

4

6

8

10

Boron nitride, wt %

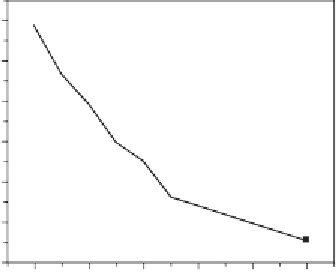

Figure 13.6

Oxygen permeability of the composites as a function of boron nitride content

at a pressure of 0.010 MPa [23].

Polymer-based composites which have been shown to provide barrier

to oxygen are being studied for packaging applications. h e oxygen per-

meability of virgin chitosan and chitosan/BN composites can be seen in

Figure 13.6. As chitosan is a porous polymer, the dispersion of boron nitride

in chitosan matrix may provide the huddles for oxygen entrance, whereas

virgin chitosan may have voids for oxygen permeation [23]. Oxygen per-

meability of chitosan/BN composites was conducted to measure the ef ect

of boron nitride concentrations on the chitosan matrix. h e oxygen l ow

rate through all the composites was observed to be less in comparison with

the virgin chitosan at pressure 0.010 MPa (Figure 13.6). It was found that

the l ow rate decreased with an increase in percentages of boron nitride

loading. h e substantial reduction in oxygen permeability may be due to

the dispersion of boron nitride within the chitosan matrix. h e oxygen l ow

rates through all composites were also observed to be less in comparison

with the virgin chitosan at dif erent pressures up to 0.013 MPa.

Oxygen permeability of the synthesized cellulose/BN nanobiocompos-

ites was conducted to measure the ef ect of boron nitride concentrations

on oxygen barrier properties of the cellulose matrix [24]. h e oxygen l ow

rate through all the nanobiocomposites was observed to be less in compar-

ison to the virgin cellulose at constant pressures of 2 psi (Figure 13.7a). It

was found that the l ow rate was decreased with an increase in percentage

of boron nitride loading. h e remarkable reduction in oxygen permeability

was due to nanostructure dispersion of boron nitride within the cellulose

matrix at dif erence pressure up to 2 psi (Figure 13.7b).

Search WWH ::

Custom Search