Environmental Engineering Reference

In-Depth Information

10

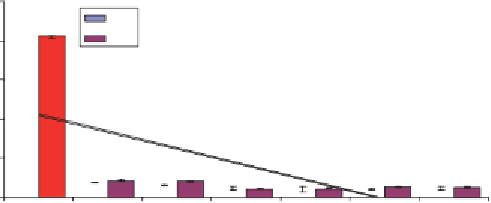

PF

UP

PF: y = -0.8596x + 5.0557

R

2

= 0.4098

UP: y = -0.8604x + 5.1257

R

2

= 0.4183

8.19 a

8

6

4

2

0.87 b

0.79 c

0.53 d

0.49 d

0.44 d

0.48 d

0.75 b

0.63 c

0.46 d

0.41 d

0.42 d

0.46 d

0

Control

1000

900

800

700

600

500

Impregnation pressure (mmHg)

Figure 5.3

MC of PF- and UP-impregnated sugar palm i bers at various impregnation

pressures.

observed when pressure increased from 700 and 500 mmHg. It was also

observed that the rate of moisture absorption was not much dif erent

between PF-impregnated i bers and UP-impregnated i bers, as shown by

the slope in the respective regression trend lines.

It was expected that the i ber without impregnation would have much

higher MC due to absorption of moisture into its cell wall. h is can be

attributed to the hydrophilic property of natural i bers where hydrogen

bonding is formed between the hydroxyl groups and water molecules

[31-34]. h is is due to the fact that natural i ber contains hydroxyl or OH

groups, which are present throughout its structure and attract and hold

water molecules by the mechanism of chemical bonding called hydrogen

bonding. When natural i bers are exposed to a surrounding atmosphere

containing high humidity, initially water molecules are absorbed directly

onto the hydrophilic groups of the i ber, followed by other water molecules

attracting to other hydrophilic groups; they also may form further layers

on top of the water molecules that have already been absorbed [35]. h is

absorption continues until the equilibrium moisture content (EMC) with

the surrounding air is attained. h is study has successfully proven that the

penetration of moisture and the formation of hydrogen bonds are inhib-

ited by enclosing the i ber with hydrophobic materials of polymer resin via

a i ber-resin impregnation process. With impregnation and polymeriza-

tion, the natural i bers became moisture resistant as they were enclosed

with cured resin that would expel moisture from the i ber. h is can be bet-

ter understood by observing the optical micrographs (400x) (Figs. 5.4a-g)

that show the i bers enclosed with the resin at er being impregnated. h e

surface of the control sample (Fig. 5.4a) was signii cantly dif erent than the

surface of the UP-impregnated i bers (Figs. 5.4b-g).

Search WWH ::

Custom Search