Graphics Reference

In-Depth Information

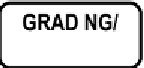

4.6.6 Tests

Assuming that you have the appropriate target specii cations for the geometry

workl ow, your next step is to conduct a feasibility test of the various tools and

techniques in light of the targets. Once the feasibility tests have determined

the appropriate tools and techniques to meet the targets, then you move on

to stress testing the tools and techniques under conditions simulating full

production.

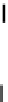

Key questions the geometry team can ask about tests for each process area in

the geometry workl ow are shown in

Figure 4.19

.

PROCESS

FACTORS

INPUT/

OUTPUT

How do you know your geometry tools

can accommodate projected workload?

How do you know tools are calibrated to

common standard?

CALIBRATION

How does the viewing environment

differ from final venue?

VIEWING

TESTS

Do your tools perform as expected?

ANALYSIS

GRADING/

CORRECTION

Can your tools handle the projected

workload?

QUALITY

CONTROL

How do you know that other workflows

will preserve geometry decisions?

Figure 4.17

Key questions the geometry team can ask about tests for each process

area in the geometry workl ow.

Search WWH ::

Custom Search