Environmental Engineering Reference

In-Depth Information

Physically

adsorbed moisture

Step 1

NP

5.1 g

NP

NP

+

C:1.03 g

NP

P:1.42 g

Physicochemical

adsorption of catalyst

and promoter

Ultrasonic bath: 30 min

Step 2

P

NP

7.7 g monomers

Ultrasonic bath: 6h

Step 3

THF

NP

NP/PU

composite

SIP NP/PU

Aluminum mold:

3 days

Hot press: 130°C

10 min

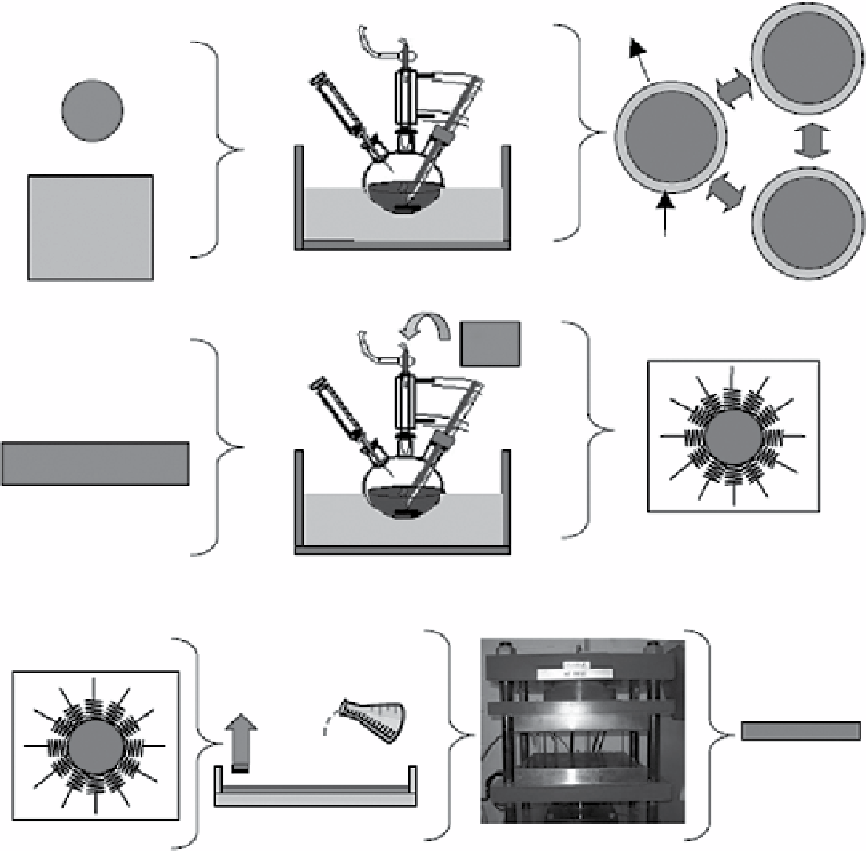

figure 4.1

Schematic of the surface-initiated polymerization (SIP) process. Adapted with permission from Ref. [16]. © IOP.

magnetic and dielectric properties. The PNC samples synthesized using the SIP method showed negative permittivity in contrast

to the positive real permittivity in the PNCs prepared by physical mixing. Moreover, positive MR was observed in all the PNCs,

which was analyzed by the wave function shrinkage model. The external magnetic field contracted the electronic wave function

at the impurity center, while the introduction of barium titanate reduced the contraction effect and thus PNCs showed lower

magnetic resistance than the neat PANI.

The MSP method usually avoids the use of additional surfactants, but instead the monomer itself serves as the coupling

agent with one end bonding to the NP surface and the other continuing polymerization with other monomers, thus forming a

well-dispersed and uniform PNC network. For example, through this unique MSP method, a robust entity of Fe/vinyl ester

resin nanocomposites was fabricated, which demonstrated enhanced mechanical strength [17]. Figure 4.2 shows a scheme in

which iron NPs are stabilized by vinyl ester monomer and facilitate further polymerization with other monomers, thus forming

the interconnecting system. In addition, we have also successfully prepared PP- and Pe-based PNCs by in situ thermal decom-

position of the organometallic iron precursor in the polymer solution at high temperatures [19-22] in which size- and phase-

controlled iron NPs were synthesized in situ and uniformly dispersed in the polymer matrix to form PP or Pe magnetic

nanocomposites.