Environmental Engineering Reference

In-Depth Information

(a)

(b)

(c)

(d)

(e)

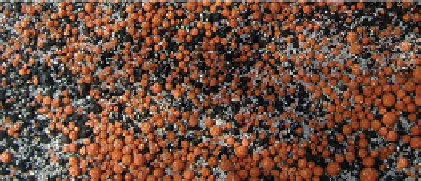

fiGure 1.4

Morphology of common gas bubbles associated with n-Fe

0

(nanofer Star (supplied by nanoiron s.r.o.; www.nanoiron.cz),

50 nm, BET = 20m

2

g

−1

; mixed with n-Al

0

and n-Cu

0

) (a) Oxygen bubbles encased by Cu

0

on the surface of n-Fe

0

[5 g n-Fe

0

+ 5 g n-Cu

0

+ 0.25 l

saline H

2

O [Eh = 0.095 V; pH = 7.01; EC = 1.993 mS cm

−1

; T = 12.8 C - gas composition checked using TCD GC]]. (b) O

2

gas venting where

n-Al

0

rests on top of n-Fe

0

. The O

2

gas bubbles are encased by n-Cu

0

. [5 g n-Fe

0

+ 5 g n-Cu

0

+ 5 g n-Al

0

+ 0.25 l saline H

2

O [Eh = 0.073 V;

pH = 7.00; EC = 1.981 mS cm

−1

; T = 12.9 C- gas composition checked using TCD GC]]. (c) O

2

gas venting where n-Al

0

rests on top of n-Fe

0

.

[5 g n-Fe

0

+ 5 g n-Cu

0

+ 5 g n-Al

0

+ 0.25 l saline H

2

O [Eh = 0.073 V; pH = 7.00; EC = 1.981 mS cm

−1

; T = 12.9 C- gas composition checked using

TCD GC]]. (d) O

2

filled spheres of n-Cu

0

developing on the n-Fe

0

- water interface, 5 min after loading into a reactor. [40% n-Fe

0

+ 20%

n-Cu

0

+ 40% n-Al

0

]. (e) H

2

gas bubbles developing on the ZVM-water interface (Fig. 1.4d), 3 weeks after loading [H

2

composition verified by

TCD GC]. Part of the n-Fe

0

has been corroded to form agglomerated FeOOH and Fe

3

O

4

nodules or clods (0.5-4 mm in diameter). Some of

the nodules are coated with n-Cu

0

. Each nodule forms an accreting galvanic cell (Fig. 1.2) with an anodic core (e.g., n-Fe

0

, n-Al

0

, Fe(OH)

2

)

and a cathodic exterior (e.g., n-Cu

0

, n-FeOOH, n-Fe

3

O

4

). Individual gas bubbles are 3-6 mm in diameter.

After the FeOOH corrosion products (Fig. 1.2) reach a critical mass, the ZVM switches from operating in a net recharge mode,

to operation in a net discharge mode. During this phase, distinctive hydrogen gas bubbles form on the ZVM/FeOOH surface

(Fig. 1.4e). Unlike the O

2

bubbles, H

2

bubbles are not associated with a specific cathodic ZVM, but instead form on the surface

(and in) active charge transfer sites (e.g., FeOOH, Fe

3

O

4

(Fig. 1.4e)).

1.3.3.2.2.6 galvanic type b reactions: hydrogen evolution The amount of hydrogen generated is a function of ZVM

composition, water composition, and operating conditions (pressure, temperature) [155-157]. The maximum hydrogen produc-

tion occurs when the n-ZVM is reduced to the ZVM oxide (Fig. 1.2). For example,

x

ZVM +

y

H

2

O = ZVM

x

O

y

+

y

H

2

. For the

reaction 3Fe + 4H

2

O = Fe

3

O

4

+ 4H

2

(Figs. 1.2 and 1.4e), 167 g n-Fe

0

(50 nm) + 72 g H

2

O = Fe

3

O

4

+ 8 g H

2

(89.64 l) [158]. This pro-

cess can be undertaken over a short time period using n-Fe

0

(50 nm). Increasing the temperature of a water:n-Fe

0

mixture from

<20 to 350°C over a 90-min period, in a sealed diffusion reactor, will result in a H

2

yield of about 450-540 m

3

H

2

t

−1

n-Fe

0

, and

a gas pressure of greater than 5 MPa [159]. Cooling the reactor to 20°C provides a deliverable H

2

gas at less than 3 MPa [159].

Reduction of the Fe

3

O

4

to Fe

0

allows the cycle to be repeated (e.g., Fe

3

O

4

+ 4CO = 3Fe

0

+ 4CO

2

; Fe

3

O

4

+ 4H

2

= 3Fe

0

+ 4H

2

O) [159,

160]. In a confined diffusion reactor, the general reactions (Fig. 1.2), result (at

T

= <50°C) in low levels of pressurized H

2

gas

evolution as the Fe

0

oscillates between charged (Fe

III

) and discharged (Fe

II

) states [155-157].

The oscillating combination of H

+

and e

−

generation from the cathodic sites during recharge and discharge [151, 153] creates

the driving force for chlorinated hydrocarbon (and other Type A) remediation [161].