Environmental Engineering Reference

In-Depth Information

12

DM

SIP

10

8

6

4

2

0

0

200

400 600

Tensile strain (%)

800

1000

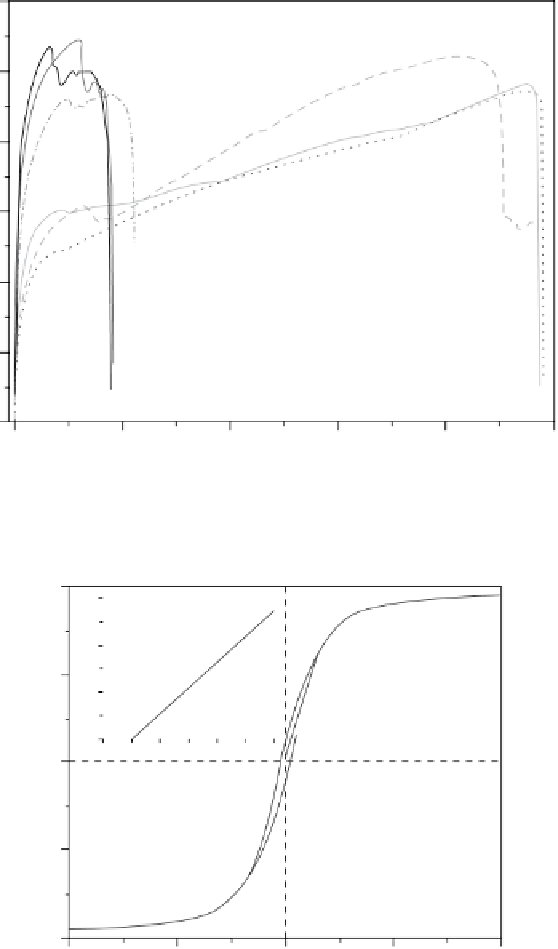

figure 4.5

Tensile stress-strain curves of 65 wt% nanocomposites fabricated by the DM and SIP methods; insets show the optical micro-

graphs of composites obtained using DM (left), pure polyurethane (middle), SIP (right). Adapted with permission from Ref. [16]. © IOP.

10

1.5

M

r

= 1.36 emu/g

1.0

5

496 Oe

0.5

0.0

-600

-400

-200

0

0

(a)

(b)

-5

MGNCs

-10

-20,000

-10,000

0

10,000

20,000

Magnetic eld (Oe)

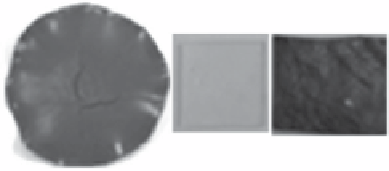

figure 4.6

Room-temperature hysteresis loop of MGNCs. Top inset shows the enlarged partial curve and bottom inset shows MGNCs

dispersed in acid and magnetic separation. Adapted with permission from Ref. [25]. © ACS.

the MR properties of carbon nanostructure-derivatized PANI-based nanocomposites at two different temperatures; at the lower

temperature of 130 K, all samples demonstrated small, negative MR, while at the higher temperature of 290 K all samples

showed large, positive MR. This phenomenon indicated that at different temperatures, electron transport is affected differently

by the external magnetic field, which further indicates that at different temperatures, electron transport takes place via different

mechanisms.

4.3.4

rheological analysis of Multifunctional nanocomposites

Dispersion of nanofillers in a polymer or carbon matrix may have a significant impact on the rheological behavior, which

subsequently affects the processing and properties of multifunctional nanocomposites. The difference in rheological behavior

can in turn provide insights into the structural variations of nanofillers in host polymer or carbon matrix. The characteristic