Environmental Engineering Reference

In-Depth Information

cooling as well as heat. It produces 170-175

◦

C water which powers a double-effect

absorption chiller. Where needed, the thermal energy can be converted into electricity

(Gee et al., 2003).

The companies Absolicon Solar and Arontis Solar offer two parabolic trough sys-

tems (T10 and MT10) very similar to the one described in 17.2.3.3, but with thermal

absorbers. The T10 system is prepared for domestic solar heating and the MT10

for steam and process heat industrial applications (Absolicon Solar Concentrator AB,

2012).

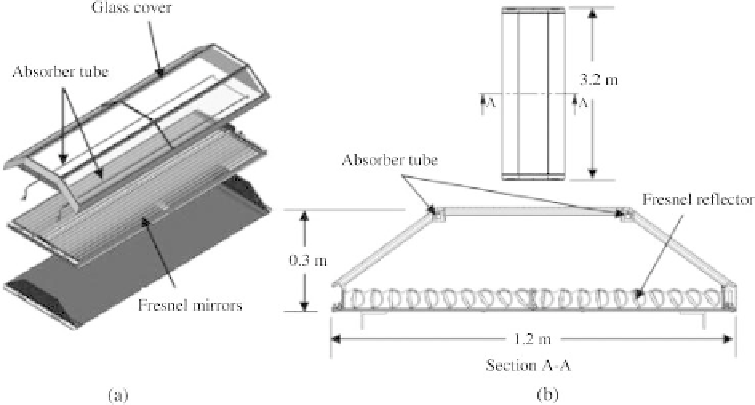

2) Solar collectors with Micro-Concentrators (MCT)

A representative example of this type of technology is the system commercialized

by Chromasun Solar company. Chromasun and its partners in 2011 activated a

60-collector SCT system at Santa Clara University (SCU) to heat water (the largest

rooftop concentrating solar thermal installation in California). The installation is

shown in Figure 17.2.15a. From Figure 17.2.15b it can be seen the Fresnel reflec-

tor shape which focuses irradiance onto the absorber tube under a concentration ratio

of 20-30X. From outside, the MCT has a flat-panel format. Like flat-panel collectors,

MCT is easy to install, weighs about the same and is easy to look after. MCTs can

produce much higher temperatures and efficiencies than a flat-plate collector and has a

much smaller package. The MCT has been designed purposely for rooftop integration

(Sultana et al., 2012).

In relation to “micro'' systems, it should be mentioned that in the field of CSP there

is a tendency for development of “compact'' devices (Micro-scaled Concentrated Solar

Power (MicroCSP)) in order to facilitate their building integration. An example is a

Micro CSP system for air-conditioning from the company Sopogy® (Sopogy, 2012).

Figure 17.2.15

(a) Exploded view of a solar micro-concentrator system and (b) Cross-section of the

MCT collector (Sultana et al., 2012).

Search WWH ::

Custom Search