Environmental Engineering Reference

In-Depth Information

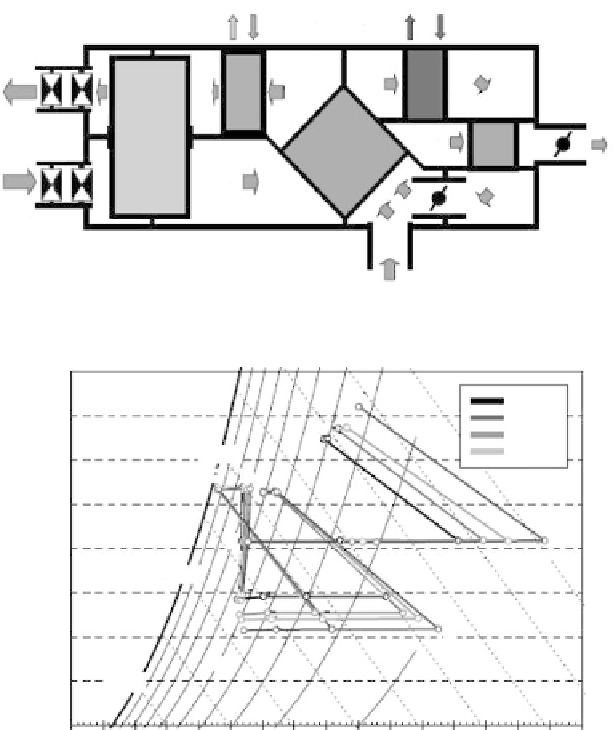

(a)

WARM

WATER

HOT

WATER

WATER

OUT

WATER

IN

A

H

C

D

E

C

4'

5'

12

F N F N

10

9

11

EXIT

AIR

HEAT

EXCHANGER

[HEX-1]

4

HEX[2]

5

SUPPLY

AIR

1

F N F N

3

2

8

6

OUTDOOR

AIR

RETURN

AIR

7

(b)

0.022

11 12

11 12

11 12

11 12

60

°

C RT

0.020

65

°

C RT

70

°

C RT

70 kJ/kg

75

°

C RT

0.018

6

5

12

0.016

99 9 9

8

0.014

10 10

10

10

50 kJ/kg

4

0.012

4

4

3

5

5

3

4

3

5

4

4

4

3

0.010

4

50

0.008

30 kJ/kg

0.006

0

5 0 5 0 5 0 5

Dry Bulb Temperature (

40

45

50

55

60

65

70

75

80

C)

Figure 16.3.2

Constant humidity ratio supply air solid desiccant air-conditioning system: a) system

diagram; b) psychrometric chart (Enteria et al., 2010b; Enteria et al., 2010c).

it has lower regeneration temperature requirements with higher COP. Kodama et al.

(2005) show the multi-pass desiccant wheel presented in Figure 16.3.4. This shows

that a 50

◦

C regeneration temperature is enough for the desiccant wheel. Furthermore,

Kodama et al. (2003) presented several designs of the desiccant air-conditioning system

for humid climates, conditions in which the 4-wheel cycle (two desiccant wheels and

two heat wheels) can be used. However, the 3-wheel cycle (1 desiccant wheel, 1 heat

wheel and 1 total heat exchanger) proved better than the 4-wheel cycle.

The fixed-bed solid desiccant air-conditioning system is another type of modified

system, on which several design studies have been conducted. The advantage of the

fixed-bed system is the sorption process, which can be done in an isothermal way.

Search WWH ::

Custom Search