Environmental Engineering Reference

In-Depth Information

cooling application, this is done through temperature, compared to industrial appli-

cations of pressure. The processed (dehumidified) air is pre-cooled through, in most

cases, the rotating heat wheel, either through utilization of the cool return air or by

means of outside air. As the air in most cases is still warm for application indoors, final

air cooling is done by means of evaporative cooling, or chill cooling.

The solid desiccant air-conditioning system is the most widely used desiccant air-

conditioning system. This is due to the simple handling of desiccant materials. The

desiccant material is typically impregnated to the honeycomb designed wheels or to

the cross-flow heat exchangers. Although typical solid desiccant materials have higher

regeneration temperatures than liquid desiccants, new materials have been developed

with lower regeneration temperature requirements.

16.3.2 Typical systems

Solid desiccant air-conditioning systems are simpler to use and apply due to the easy

handling of the desiccant material. Hence, the system is not complicated, unlike

liquid desiccant air-conditioning systems in both design and operation. Farooq and

Ruthven (1991) investigated the desiccant bed for solar air-conditioning application.

They showed that the optimal choice of desiccant can be compensated by the appropri-

ate adjustment of the cyclic time. In addition, the cost of making the desiccant wheel

and moisture diffusivity should be given consideration. Jurinak et al. (1984) presented

the open-cycle desiccant air-conditioning system both for ventilation cycle and recir-

culation cycle. They showed that unbalancing the air flow through the dehumidifier

improved the desiccant system coefficient of performance (COP) by 10-15% for the

ventilation cycle and up to 50% for the recirculation cycle. To make the desiccant air-

conditioning system competitive, the thermal COP of the high-performance desiccant

systems must be improved to compete with conventional vapour compression systems,

such as very high heat and mass transfer unit dehumidifiers with large thermal capac-

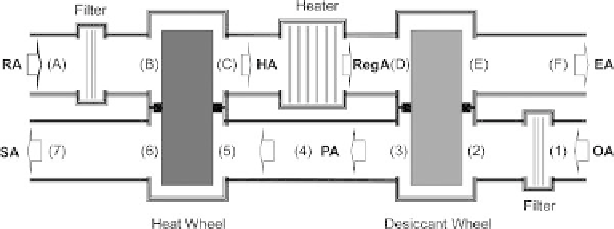

itance matrix. The most common solid desiccant air-conditioning system is composed

of the two-wheel type, the so-called Munter Cycle shown in Figure 16.3.1. This is the

basic design of the solid desiccant air-conditioning system, in which application of the

air cooling in both the supply air and in the return air is implemented. Hence, several

modifications to this cycle, implementing different operating strategies, are presented

by Henning et al., 2007, Jain et al., 1995 and Henning et al., 1995.

Figure 16.3.1

The double wheels type solid desiccant air-conditioning system (Enteria et al., 2010a).

Search WWH ::

Custom Search