Environmental Engineering Reference

In-Depth Information

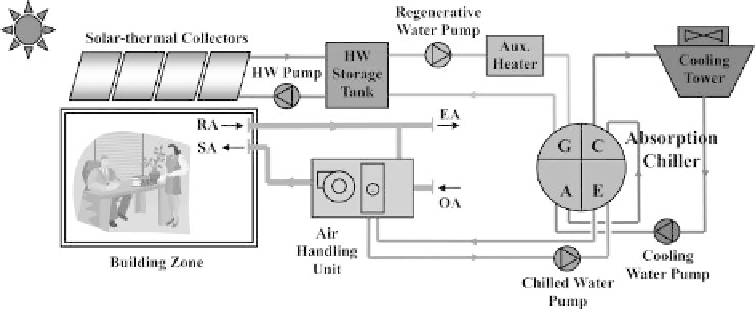

Figure 15.2.2

Solar absorption refrigeration system for space conditioning. (Abbreviation:A: absorber;

C: condenser; E: evaporator; EA: exhaust air; G: generator; HW: hot water; OA: outdoor

air; RA: room air; and SA: supply air).

When the absorption chiller is operating, the cooling tower removes heat from both

the absorber and the condenser in series. The common working pairs are lithium bro-

mide/water and water/ammonia. For a typical single-effect LiBr-H

2

O absorption chiller

the driving temperature is generally between 70

◦

C and 90

◦

C, which can be primarily

achieved by solar-thermal gain, together with the assistance of auxiliary heating.

15.2.2.2 Solar adsorption refrigeration

Adsorption chillers have a relatively low driving temperature by using an appropriate

working pair of adsorbent and refrigerant. The schematic diagram of a solar adsorp-

tion refrigeration system is presented in Figure 15.2.3. Generally it is similar to that of

solar absorption refrigeration, except that an adsorption chiller is used. The econom-

ical adsorption pair is silica gel and water, where silica gel is the adsorbent and water

the refrigerant. Other effective adsorption pairs include zeolite/water and activated

carbon/ammonia. Compared to the absorption cycle, its driving temperature can be

down to about 60

◦

C. Typically, there are two chambers containing adsorbent in the

adsorption chiller. While one chamber is used for adsorption, the other is used for des-

orption. Their roles are interchanged according to the period of adsorption/desorption

process (usually 6 minutes for the silica gel/water pair). A pseudo-continuous operation

is therefore formed in the refrigeration cycle. Cooling water and regenerative water are

fed into the adsorption chamber and the desorption chamber respectively, and these

two water circuits are alternatively changed according to the role of the chamber.

15.2.2.3 Solar desiccant cooling

A solar desiccant cooling system can directly provide conditioned air to the building

zone, as shown in Figure 15.2.4. The core part of this system is the desiccant com-

ponent, and both solid and liquid sorbents, such as silica gel and lithium chloride

respectively, can be applied. Although desiccant cooling using liquid sorbent has the

Search WWH ::

Custom Search