Environmental Engineering Reference

In-Depth Information

manufacturing techniques (Duffie and Beckman, 1991) to ensure good thermal contact

between the tubes and the plate.

4.1.3 Evacuated tube collectors

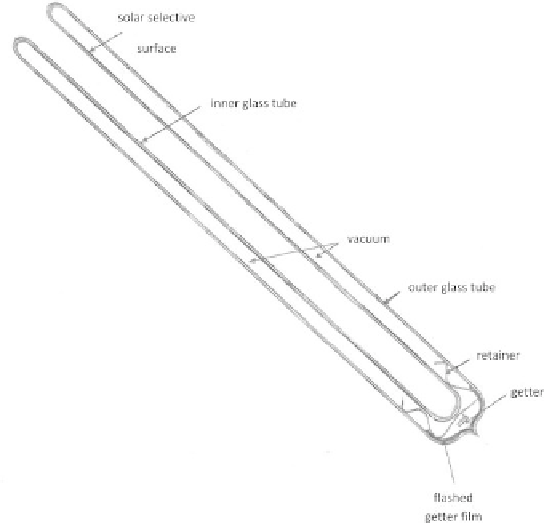

Evacuated-tube collectors are fabricated from either concentric glass tubes or a metal

tube end-sealed to and within a glass tube. An enclosed evacuated annular space and a

selective absorber surface provide a very low overall heat loss particularly when oper-

ated at higher temperatures. The evacuated space between the glazing and absorber

eliminates convective loss and long-wave thermal radiative heat loss is inhibited by

the deposition of the spectrally selective absorber coating on the absorber surface

(Morrison, 2001). Evacuated-tube solar collectors generally have low thermal mass.

The ability to heat-up rapidly (often from higher maintained overnight temperatures

than a flat plate collector) gives low utilizable insolation thresholds providing good

low insolation performance. Heat removal in evacuated tube collectors can be indirect

often using a volatile fluid in the absorber via a closed heat pipe (Tabassum et al.,

1988). More frequently water, as a heat transfer fluid, moving in a thermosyphon

through the collector is employed (Morrison, 2001, Budihardjo and Morrison, 2007).

Evacuated tube collectors can have copper absorbers or use a selectively coated glass

inner glass tube as the absorber. The latter all-glass type is now commonplace in China

with over 15 million square metres of collector area installed by 2010 (Norton, 2011).

A typical example of an evacuated tube collector is show in Figure 4.1.2.

Figure 4.1.2

An all-glass “wet type'' evacuated tube solar energy collector.

Search WWH ::

Custom Search