Environmental Engineering Reference

In-Depth Information

TABLE 6.22

Results from Fugacity Level II Calculations for Air and

Water Concentrations

K

aw

K

sw

C

i

a

C

i

w

(Pa

−1

m

−3

mol

−1

)(L

−1

kg)

(mol

−1

m

3

)

(mol

−1

m

3

)

I

INGTP

i

Chemical

I

INHTP

i

Benzene

557

5

0.11

0.50

1.0

1.0

Toluene

676

20

0.10

0.42

42

12

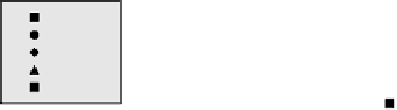

Figure 6.76 shows the results of the calculations of risks for various categories as a

function of the process variable, the absorption oil flow rate.

I

GWP

decreases consid-

erably and reaches a minimum at about 50 kg mol/h of oil flow rate. The optimum

therefore with respect to global warming is to work around this value. Initially when

there is no oil flow, all of the VOCs are released to the air and gradually converted

to CO

2

elevating the global warming impact. However, as the oil flow rate increases,

more of the VOCs are recovered and recycled reducing the global warming impact.

As the oil flow rate increases above 50 kg mol/h, the process utilities increase the

emission of CO

2

and therefore negate any advantages due to increased recovery of

VOCs. The smog formation potential,

I

SFP

, appears to decrease considerably above

100 kg mol/h of oil flow rate. Hence, the maximum reduction in the smog formation

potential can be realized at the highest oil flow rate achievable. This also coincides

10

4

1000

100

GWP

SFP

ARP

INGTP

INHTP

10

1

0.1

0

100

200

300

400

500

600

Oil flow rate/kg

mol ∙ h

-1

FIGURE 6.76

Calculated risks for different categories as a function of the absorption

oil flow rate.

Search WWH ::

Custom Search