Environmental Engineering Reference

In-Depth Information

(CO

2

and NO

x

)

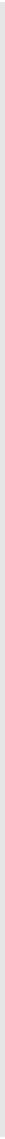

. Figure 6.75 is the overall process flow sheet. The stream that consists

of 200 kg/h of benzene and toluene is introduced first into an absorption column where

nonvolatile absorption oil is used to strip the benzene and toluene from the stream. The

oil is distilled to separate the benzene and toluene for reuse within the manufacturing

process. The oil is then recycled into the absorption column. The primary emissions

from the process occur through the vents, storage tanks, and other fugitive sources and

consist of traces of benzene, toluene, and utility gases (CO

2

,NO

x

)

. These emissions

are dependent on the oil flow rate through the absorption column. We need to determine

the overall environmental impacts from this process and how they can be minimized

as we change the process parameter, namely, oil flow rate. The methodology described

here follows closely that given in Allen and Shonnard (2002).

Vent

(recovery

of Bz, Tol)

Vent

Oil

Products

Benzene,

toluene

200 kg/h

Absorption

Distillation

FIGURE 6.75

Overall process flow sheet for a typical chemical manufacturing

process.

Table 6.20 lists the various emission rates resulting from the process schematic given

in Figure 6.75. Ideally, one would use a commercial process simulator such as HYSIS,

ASPEN, or SimSci to carry out mass and energy balances on the various system com-

ponents and calculate the emission rates of different species generated in the process.

In doing so, one will have to use the standard EPA emission factors that are listed for

specific pollutants. We have circumvented that process to generate Table 6.20 using

hypothetical values for the process as an illustration of the calculation of environmen-

tal impact indices. The emission rate for benzene rapidly decreases with increasing oil

flowrate,whereasthatfortoluenedecreasesmuchmoreslowly.Withincreasingoilflow

rates, the utility systems emit more of CO

2

and NO

x

. Typical physicochemical proper-

ties required for the calculation will have to be obtained from thermodynamic arguments

presented in Chapters 2 and 3 or from standard tables such as given in Appendix 1.

Search WWH ::

Custom Search