Environmental Engineering Reference

In-Depth Information

1.0

Removal with

tailing

0.5

heoretical

removal

0

0

1

2

Water-filled aquifer volume

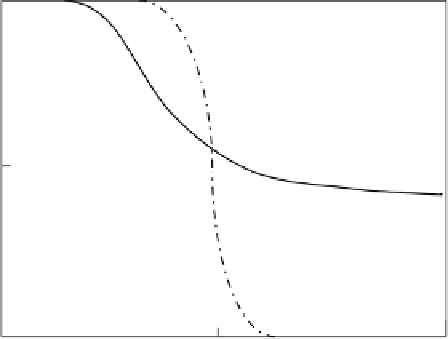

FIGURE 6.61

Phenomena of tailing-off in conventional P&T process for groundwater

remediation.

The process can be modeled by considering the aquifer to be a completely mixed

reactor (CSTR). If we consider a total volume

V

T

of the aquifer, the fluid volume is

ε

is the porosity of solids.A mass balance on the continuous reactor gives

the following:

V

T

, where

ε

rate in with water

=

rate out with water

+

accumulation rate (solids

+

pore fluid

)

.

d

[

]

d

t

+

A

d

W

A

d

t

.

Q

[

A

]

in

=

Q

[

A

]+

V

T

(

1

−

)V

T

ρ

s

(6.217)

If local equilibrium between solids and pore fluid is assumed,

W

A

=

K

sw

[A]. More-

over, if pure water is brought into contact from the injection well, [A]

in

=

0.

Hence,

Q

R

F

[

]

V

T

=

A

d

[

]

d

t

,

A

−

(6.218)

where

Q

is the volumetric flow rate and

R

F

= ε +

(

1

− ε

)

ρ

s

K

sw

is the retardation

factor. Integrating the above equation gives

exp

.

[

]

A

Qt

R

F

V

T

]

0

=

−

(6.219)

[

A

Hence, the time taken to flush 50% of the contaminant in porewater will be

t

1

/

2

=

0.693

(R

F

V

T

/Q)

. Thus, cleanup time will increase with increasing

R

F

and decreasing

Q

. Note that

[

A

]

0

=

M

0

/V

T

R

F

, where

M

0

is the total initial mass of the contaminant.

Note that

(Qt/

ε

V

T

)

is the number of pore volumes,

N

PV

flushed in time

t

. Therefore,

[

exp

.

A

]

−

N

PV

R

F

]

0

=

(6.220)

[

A

Search WWH ::

Custom Search