Environmental Engineering Reference

In-Depth Information

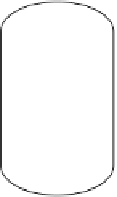

(a)

(b)

Feed

Euent

Batch reactor

(completely mixed)

CSTR (completely mixed)

Feed

(c)

Euent

PFR (no mixing)

FIGURE 6.1

Different types of ideal reactors used in environmental engineering processes.

(a)A batch reactor where there is uniform concentration in the reactor. (b)A CSTR where there

is uniform mixing and composition everywhere within the reactor and at the exit. (c) A PFR

where there is no mixing between the earlier and later entering fluid packets.

inhis

Traitéélémentairedechimie

.HisobservationstranslatedintoEnglish(

Chemical

and Engineering News

, September 12, 1994) reads as follows:

For nothing is created, either in the operations of art, or in those of nature, and

one can state as a principle that in every operation there is an equal quantity of

material before and after operation; that the quality and quantity of the [simple]

principles are the same, and that there are nothing but changes, modifications.

We have used the conservation of mass in several examples in earlier chapters.

The examples involved the equilibrium partitioning between different environmental

compartments;inthischapterwegeneralizeittochemicalsystemsinvolvingtransport

and transformations. We establish a control volume as shown in Figure 6.2, where

the general case of a continuous system is represented. The feed rate of solute

j

is

F

j

0

(moles/time). The effluent rate from the system is

F

j

(moles/time). If

r

represents the

rate of the reaction, then

Vv

j

r

represents the rate of generation of

j

(moles/time). Note

that

v

j

is the stoichiometric coefficient of

j

for the reaction as shown in Chapter 5.

A total mass (mole) balance within the reactor is then written as (Schmidt, 2005)

[

accumulation

]=[

input

]−[

output

]+[

generation by reaction

]

d

N

j

d

t

=

F

j

0

−

F

j

+

Vv

j

r

.

(6.1)

Search WWH ::

Custom Search