Hardware Reference

In-Depth Information

ergo.com

)

, and SIIG (

www.siig.com

). Many of these vendors sell through the OEM mar-

ket,soyoumustlookcarefullyatthedetailedspecificationsforthekeyboardtoseewheth-

er it is a mechanical keyswitch model.

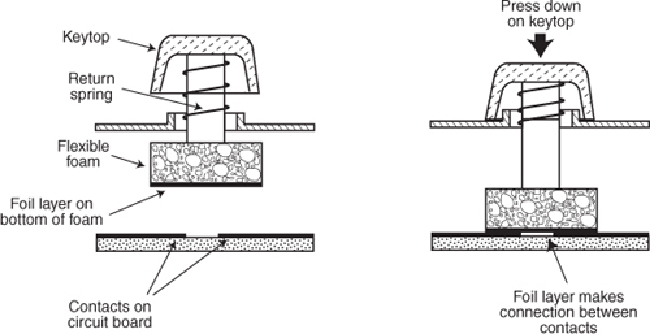

Foam Element Switches

Foam element mechanical switches were a popular design in some older keyboards. Most

of the older PC keyboards, including models made by Key Tronic and many others, used

this technology. These switches are characterized by a foam element with an electrical

contact on the bottom. This foam element is mounted on the bottom of a plunger that is

attached to the key (see

Figure 15.3

).

Figure 15.3

Typical foam element mechanical keyswitch.

When the switch is pressed, a foil conductor on the bottom of the foam element closes a

circuit on the printed circuit board below. A return spring pushes the key back up when

the pressure is released. The foam dampens the contact, helping to prevent bounce, but it

givesthesekeyboardsa“mushy”feel.Thebigproblemwiththistypeofkeyswitchdesign

is that little tactile feedback often exists. These types of keyboards send a clicking sound

to the system speaker to signify that contact has been made. Preferences in keyboard feel

are somewhat subjective; I do not favor the foam element switch design.

Another problem with this type of design is that it is more subject to corrosion on the foil

conductor and the circuit board traces below. When this happens, the key strikes can be-

come intermittent, which can be frustrating. Fortunately, these keyboards are among the

easiest to clean. By disassembling the keyboard completely, you usually can remove the

circuit board portion—without removing each foam pad separately—and expose the bot-

toms of all the pads. Then, you easily can wipe the corrosion and dirt off the bottoms of