Hardware Reference

In-Depth Information

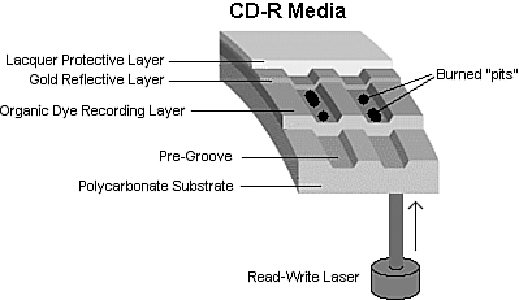

laser is fired in a pulsed fashion at the top of the ridge (groove), heating the layer of or-

ganicdyetobetween482°Fand572°F(250°-300°C).Thistemperatureliterallyburnsthe

organic dye,causing ittobecome opaque.Whenread,thisprevents thelight frompassing

through the dye layer to the gold and reflecting back, having the same effect of canceling

the laser reflection that an actual raised pit would on a normal stamped CD.

Figure 11.6

shows the CD-R media layers, along with the pre-groove (raised ridge from

the laser perspective) with burned pits.

Figure 11.6

CD-R media layers.

The drive reading the disc is fooled into thinking a pit exists, but no actual pit ex-

ists—there's simply a spot of less-reflective material on the ridge. This use of heat to cre-

ate the pits in the disc is why the recording process is often referred to as

burning

a CD.

When burned, portions of the track change from a reflective to a nonreflective state. This

change of state is permanent and can't be undone, which is why CD-R is considered a

write-once medium.

CD-R Capacity

All CD-R drives can work with the original 650MiB (682MB) CD-R media (equal to

74 minutes of recorded music), as well as the now-standard higher-capacity 700MiB

(737MB) CD-R blanks (equal to 80 minutes of recorded music).

Some drives and burning software are capable of overburning, whereby they write data

partiallyintothelead-outareaandessentiallyextendthedatatrack.Thisisdefinitelyrisky

asfarascompatibility isconcerned.Manydrives,especiallyolderones,failwhenreading

near the end of an overburned disc. It's best to consider this form of overclocking CDs

somewhat experimental. It might be useful for your own purposes if it works with your

drives and software, but interchangeability will be problematic.