Hardware Reference

In-Depth Information

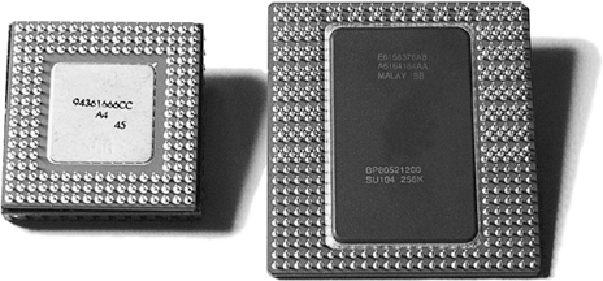

Early PGA variations mounted the processor die in a cavity under the substrate, whereas

so-called“FlipChip”versionsmounttheprocessordieupsidedownsothatlessexpensive

solder bonding rather than expensive wire bonding can be used to connect the processor

die to the chip package.

Unfortunately, there were some problems with attaching the heatsink to an FC-PGA chip.

The heatsink sat on the top of the die, which acted as a pedestal. If you pressed down

on one side of the heatsink excessively during the installation process (such as when you

were attaching the clip), you risked cracking the silicon die and destroying the chip. This

was especially a problem as heatsinks became larger and heavier and the force applied

by the clip became greater. Intel and AMD now use a metal cap called a

heat spreader

over the top of the CPU to prevent damage when the heatsink is installed. This type of

packaging is known as FC-PGA2 and was used by Intel for all Pentium 4 and subsequent

chips. AMD began to use it with its Athlon 64 processors and subsequent chips.

Future packaging directions may include what is called

bumpless build-up layer

(BBUL)

packaging. This embeds the die completely in the package; in fact, the package layers

are built up around and on top of the die, fully encapsulating it within the package. This

embeds the chip die and allows for a full flat surface for attaching the heatsink, as well

as shorter internal interconnections within the package. BBUL is designed to handle ex-

tremely high clock speeds of 20GHz or faster, but is not yet necessary.

Single Edge Contact and Single Edge Processor Packaging

Intel and AMD used cartridge- or board-based packaging for some of their processors

from1997through2000.Thispackagingwascalled

single edge contact cartridge

(SECC)

or

single edge processor package

(SEPP) and consisted of the CPU and optional separate

L2 cache chips mounted on a circuit board that looked similar to an oversized memory