Hardware Reference

In-Depth Information

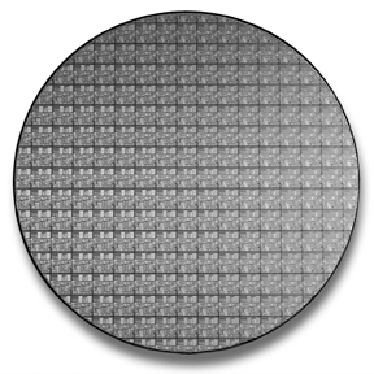

Figure 3.5

200mm (8-inch) wafer containing 177 full Pentium 4 Northwood (0.13-micron) processor

cores.

Chipsaremanufacturedfromthewafersusingaprocesscalled

photolithography

.Through

this photographic process, transistors and circuit and signal pathways are created in semi-

conductors by depositing different layers of various materials on the chip, one after the

other. Where two specific circuits intersect, a transistor or switch can form.

The photolithographic process starts when an insulating layer of silicon dioxide is grown

on the wafer through a vapor deposition process. Then a coating of photoresist material is

applied, and an image of that layer of the chip is projected through a mask onto the now

light-sensitive surface.

Doping

is the term that describes chemical impurities added to silicon (which is naturally

a nonconductor), creating a material with semiconductor properties. The projector uses a

specially created mask, which is essentially a negative of that layer of the chip etched in

chromeonaquartzplate.Modernprocessorshave20ormorelayersofmaterialdeposited

and partially etched away (each requiring a mask) and up to six or more layers of metal

interconnects.

As the light passes through a mask, the light is focused on the wafer surface, exposing the

photoresist with the image of that layer of the chip. Each individual chip image is called

a

die

. A device called a

stepper

then moves the wafer over a little bit, and the same mask

imprints another chip die immediately next to the previous one. After the entire wafer

is imprinted with a layer of material and photoresist, a caustic solution washes away the

areas where the light struck the photoresist, leaving the mask imprints of the individual