Environmental Engineering Reference

In-Depth Information

(in the case of a generator), provided that the magnetic field

B

maintains its direction. Various

forms of armature and magnetic field circuits give rise to the several types of alternating current

and direct current motors and generators.

The AC synchronous generator in an electric utility power plant rotates at a precise speed so

as to produce 60-cycle AC power. All power plants that feed into a common transmission line must

adhere to the same frequency standard. Because generators have an integral number of magnetic

poles, their rotational speeds are an integral submultiple of 60 Hz. The generators maintain a fixed

voltage in the transmission and distribution systems, while the current varies to suit the power

needs of electricity customers.

Because of electrical and mechanical losses in electric motors and generators, the output power

is less than the input power. The ratio of the output to the input powers is the efficiency

η

of the

device,

output power

input power

η

≡

(4.5)

According to the first law of thermodynamics, the difference between the input and output powers

appears as a heat flow from the device to the environment, in the amount of

times the input

power. Both electric motors and generators must be cooled when operating in order to prevent the

overheating of internal parts.

The electrical resistance

R

of the armature wire is a source of inefficiency in both generators

and motors. The electrical power lost in overcoming this resistance,

I

2

R

, increases as

I

2

whereas

the power increases as

I

, as in equation (4.3). This electrical loss thereby becomes a larger fraction

of the power output as the latter is increased. As a consequence, the electrical efficiency of motors

and generators is least at full power. For economic efficiency we would like to obtain the maximum

power for a given investment, which means operating at maximum power and, therefore, least

electrical efficiency.

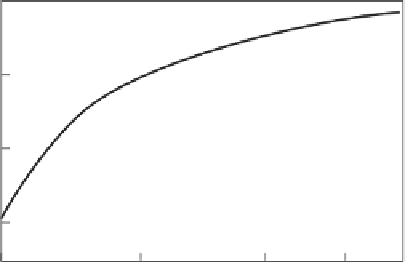

The efficiency of electric motors and generators is greater for large than for small machines.

Figure 4.4 exhibits this increase of efficiency with size for energy-efficient induction motors. The

(

1

−

η)

96

92

88

84

2

10

40

100

200

Horsepower

Figure 4.4

The efficiency of energy-efficient induction motors as a function of motor power. (Data from

Andreas, John C., 1992.

Energy-Efficient Electric Motors,

2nd edition. New York: Marcel Dekker.)