Environmental Engineering Reference

In-Depth Information

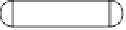

CO

2

to

compression/

dehydration

Condenser

Vent gas to

reheat stack

Reflux drum

Reflux

pump

Lean amine

cooler

Storage

tank

Booster

pump

Regenerator

(stripper)

Absorber

Cross

exchanger

Reboiler

Na

2

CO

3

MEA

reclaimer

Flue gas

from

power plant

Filtration

Sludge

Figure 10.10

Flowsheet of the monoethanolamine (MEA) process for CO

2

capture.

Solvent absorption has been used for decades for producing CO

2

from flue gas. The produced

CO

2

is used for dry ice manufacturing and for carbonated drinks, and it is used in large quantities

for enhanced oil recovery at semi-depleted oil reservoirs where the injection of high-pressure CO

2

into the reservoir helps to bring forth more oil to the surface. However, for all these uses, CO

2

is

captured from the flue gas of

natural gas

combustion. The reason is that coal and oil combustion

produce copious quantities of SO

2

,NO

x

, and other contaminants that “poison” the solvent. If coal

or oil were used as the source of CO

2

, the flue gas would have to be thoroughly purified before

entering the absorption tower, or the coal would have to be gasified before combustion.

The thermal efficiency of a coal gasification combined cycle power plant with CO

2

capture

by MEA is 30-35% compared to 40-45% without capture, and the cost increment of electricity

production is around 50%. Thus, this method is less efficient and costlier than estimated for air

separation-CO

2

recycling, but the technology is well established, whereas the oxygen combustion

technology is still in the development stage.

10.4.3.3 Membrane Separation

Gas separation by membranes relies on the different permeation rates of gases through the membrane

pores. Hydrogen, in particular, because of its small molecular size, permeates faster than any other

gas through small pores. Polymer membranes are being used commercially in recovery of hydrogen

from a purge stream in ammonia synthesis, methanol synthesis, and oil refineries. Typical membrane

examples are polysulfone/silicon, cellulose acetate, polyphenyleneoxide, polyalkene, polyimide,

polydimethylsiloxane, and polyetherimide.

The membrane method could be used for capturing CO

2

from a mixture of CO

2

and H

2

, which

is the product of coal gasification and the water shift reaction (see Section 5.3.2). This gas mixture

is subjected to membrane separation. The hydrogen permeates much faster through a membrane

than does CO

2

, and only a few stages of membrane separation would be necessary for almost 100%

separation of the gases. The separated H

2

can be used as a fuel in a gas turbine or in a fuel cell for

power production. The separated CO

2

would be compressed and sequestered.