Environmental Engineering Reference

In-Depth Information

N

2

Ar

H

2

O/CO

2

Liquid CO

2

Air

Air separation CO

2

capture

Liquid O

2

H

2

O

E

lectricit

y

Liquid CO

2

tank

O

2

CO

2

O

2

O

2

H

2

O/CO

2

H

2

O/CO

2

Coal

SG

Power

Steam

HRSG and

steam turbine

Coal gasifier

Gas turbine

H

2

O

Power

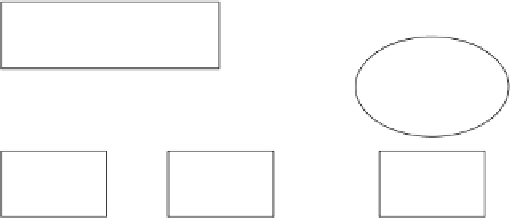

Figure 10.9

Schematic of an integrated coal gasification combined cycle power plant with CO

2

capture.

the combustion gases. The remainder consists almost entirely of CO

2

. The CO

2

is condensed in

a heat exchanger with liquid oxygen that comes from the ASU. A part of the condensed CO

2

is

recycled into the combustion chamber, and the rest is stored as a liquid for subsequent sequestering.

The estimated thermal efficiency of such a plant is about 37%, which includes the energy spent

on air separation and coal gasification. This compares to 40-45% estimated for a plant with coal

gasification, air combustion, and no CO

2

capture. The plant has a thermal efficiency comparable

to modern pulverized coal single-cycle steam plants, which emit not only the full amount of CO

2

,

but other air pollutants as well.

14

Obviously, the cost of an integrated coal gasification combined cycle plant with CO

2

capture

is higher than one without capture, and much higher than a pulverized-coal single-cycle plant. The

estimated levelized cost of electricity would increase by 10-20% compared to a coal gasification

plant without CO

2

capture, and 20-30% compared to a pulverized-coal plant with flue gas desul-

furization. The incremental cost does not include the cost of transporting and sequestering of CO

2

,

which may add another 10-20% to the cost of electricity over the no-capture plant.

10.4.3.2 Solvent Absorption

Carbon dioxide is soluble in some solvents, notably ethanolamines; e.g., monoethanolamine (MEA).

Absorption-desorption is a reversible process; absorption proceeds at low temperatures, whereas

desorption occurs at elevated temperatures:

C

2

H

4

OHNH

3

HCO

3

CO

2

C

2

H

4

OHNH

2

+

H

2

O

+

+

(10.5)

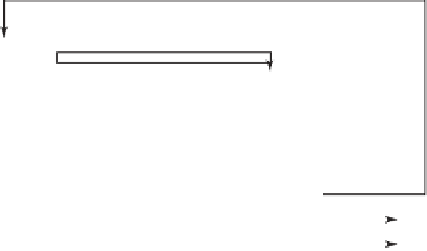

A flowsheet of the MEA process is shown in Figure 10.10. The key process units are the

absorption tower and the regeneration (stripper) tower. The absorption tower operates at 40-65

◦

C,

which means that the incoming flue gas must be cooled before entering the tower. Some pressur-

ization of CO

2

is necessary to overcome the pressure drop in the tower. The regeneration tower

operates at 100-120

◦

C, which is the major source of efficiency loss for the power plant that

uses this method. The reboiler provides the heat for the regeneration tower and for vaporizing

water.

14

Golomb, D., and Y. Shao, 1996.

Energy Convers. Manage.,

37,

903-908.