Environmental Engineering Reference

In-Depth Information

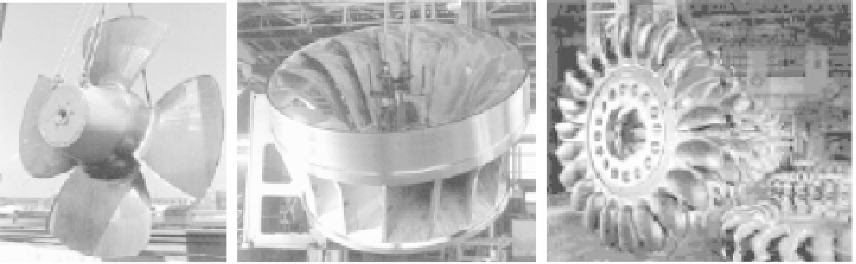

Figure 7.1

The rotating component of a hydroturbine: low-head Kaplan turbine (left), medium-head Francis

turbine (center), and high-head Pelton turbine (right). (By permission of VA TECH HYDRO.)

The technology of hydropower is well developed. Hydroturbines are rotating machines that

convert the flow of high-pressure water to mechanical power. For low-head, high-volume rate flows

the Kaplan turbine is an axial flow device that somewhat resembles a ship's propeller in shape (see

Figure 7.1). For higher heads, the Francis turbine is a radial inflow reaction turbine in which the

flow is approximately the reverse of a centrifugal pump. For very small flow rates, the Pelton wheel

utilizes a nozzle to accelerate the high-pressure water stream to a high-velocity jet that subsequently

impinges on the peripheral blades of the turbine wheel. Powering a synchronous electric generator,

hydroturbine installations can convert more than 80% of the ideal water power available to electric

power.

Most hydropower plants require the construction of a dam and spillway, the latter to bypass

excess water flow around the dam when the reservoir is full and the turbines are operating at full

capacity. The civil works required for the dam, spillway, and power house can be a considerable

fraction of the cost of the installation, so that the overall cost per unit of electrical power generation

is higher than that for the hydroturbine and generator alone. A favorable site for a hydropower

plant is one for which the cost of the civil works is not large compared to the power-producing

equipment.

An example of a hydropower installation is shown in Figure 7.2. On the far left and right is an

earthen dam that backs up the river flow, forming a higher-level pool extending miles upstream. In

the center, on the left, is a spillway that passes excess river flow; and in the center, on the right, is

a power house with five turbine-driven generators discharging water to a lower level downstream.

Given the unevenness of river flow and the finiteness of reservoir volume, hydropower plants

do not operate at their rated capacity year-round. A typical capacity factor is 50%, which represents

a compromise between the desire to utilize all the hydroenergy available in the river flow and the

necessity to limit the capital costs of doing so.

Hydroplants have indefinitely long, useful lives. The civil works and power-generating ma-

chinery are very robust, and operating expenses are very low. Many large hydropower plants have

been constructed by national governments, and their cost has been paid in part from government

revenues as well as by electricity consumers. The construction of the dam may provide benefits

other than electric power, such as water for irrigation or flood control, that reduce the costs allocated

to electricity production. Nevertheless, there are hydropower sites that can be developed that are

economically competitive with fossil fuel power plants.