Environmental Engineering Reference

In-Depth Information

5.3

ADVANCED CYCLES

We have seen that the best fossil-fueled steam power plants can achieve a thermal efficiency of close

to 40%, but the average in the United States is 36%, and the worldwide average is 33%. Power

plants that work on the gas turbine principle achieve even less, on the order of 25-30% thermal

efficiency. This means that 60-75% of the fossil fuel heating value that powers them goes to waste.

Furthermore, the emissions per kilowatt hour of electricity produced is inversely proportional to

thermal efficiency: The lower the efficiency, the more the plant pollutes and the higher the CO

2

emissions. Thus, great efforts and money are spent by private and government agencies to improve

power plant thermal efficiencies by developing advanced cycle power plants. In the United States,

research and development is sponsored by the Electric Power Research Institute and the U.S.

Department of Energy.

5.3.1

Combined Cycle

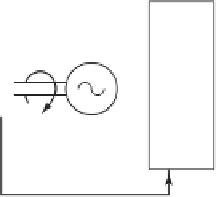

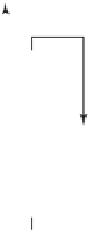

We described the thermodynamic principles of a combined cycle in Section 3.10.5. A power plant

schematic using a gas turbine combined cycle (GTCC) is shown in Figure 5.14. In the first cycle,

called the

topping

cycle, a suitable fluid fuel, usually natural gas, powers a gas turbine. The still

hot exhaust gas of the gas turbine passes through a heat exchanger, called a heat recovery boiler

(HRB), and then to the stack. In the HRB, feed water is boiled into steam that powers a steam

turbine, called a

bottoming

cycle. Sometimes, more fuel (heat) is added to the gas turbine exhaust

gas in a combustion chamber before the hot gases enter the HRB. The combination of the two

cycles can achieve a thermal efficiency of 45%, an improvement over either a single-cycle steam

turbine or a gas turbine power plant.

A problem with the combined cycle is that the primary fuel, natural gas, is more expensive

per unit heating value than coal. Also, gas reserves will not last as long as coal reserves (see

Chapter 2). Combined cycle power plants are suitable where gas supplies are plentiful and cheap

and where environmental regulations impose a heavy technical and financial burden on coal-fired

power plants. They are especially attractive in urban environments because they require practically

no fuel storage facilities (compressed gas arrives in pipes to the power plant), no particle removal

system, and no scrubber for SO

2

removal. There is also no solid waste to dispose of. However,

To stack

Heat

recovery

boiler

(HRB)

Fuel (NG or SG)

Load

Load

Gas

turbine

Steam

turbine

Generator

Generator

Cooling

tower

Hot exhaust gas

Condenser

Figure 5.14

Gas turbine combined cycle power plant, schematic.