Environmental Engineering Reference

In-Depth Information

Saturated steam

To high-pressure turbine

Steam

drum

Flue gas to stack

To low-pressure turbine

From high-pressure turbine

Boiler

Air

Feedwater

Water tubes

(risers)

Feedwater

Burner

Air

Fuel

Downcomer

Header

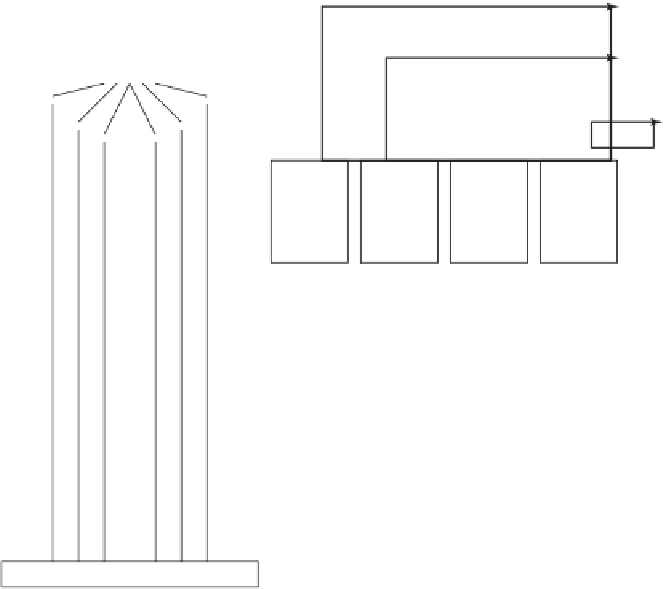

Figure 5.2

Boiler, schematic.

Figure 5.2 shows a schematic flow diagram of a common water wall boiler. Water from the

high pressure

feed water heater

at a temperature of 230-260

◦

C is further heated in the

economizer

section of the boiler to 315

◦

C, then flows into the

steam drum,

which is mounted on top of the

boiler.

5

The steam drum measures typically 30 m in length and 5 m in diameter. In the steam

drum liquid water is separated from the steam, usually by gravity. From the steam drum, liquid

water flows down the

downcomer

tubes into the

header

. From there, the hot pressurized water

flows upward (because of a negative density gradient) through the

riser

tubes, where the actual

boiling of water into steam occurs. The separated steam passes another section of the boiler,

called the

superheater,

where its temperature is raised to 565

◦

C at a pressure of 24 MPa. At this

point the temperature and pressure are higher than the critical temperature (

T

c

374

◦

C) and

=

pressure (

p

c

22 MPa) of water. The supercritical steam drives the high-pressure turbine. The

exhaust steam from the high-pressure turbine flows through the

reheater

section of the boiler, where

the temperature is raised again to about 500

◦

C at a pressure of 3.7 MPa. This steam drives the

=

5

The feed water is first heated by steam bled from the low-pressure turbine (not shown in Figure 5.2).