Environmental Engineering Reference

In-Depth Information

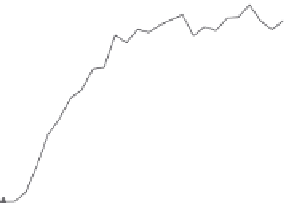

750

700

120

8 × 10

-5

mol/L

650

Al

13

Al

13agg

.2.6

Al

13agg

.2.7

Al

13agg

.2.8

600

100

550

500

80

450

400

350

60

300

10

-5

mol/L

250

40

200

150

Al

13

Al

13agg

.2.6

Al

13agg

.2.7

Al

13agg

.2.8

20

100

50

0

0

-50

0

200

400

600

800

1000

0

200

400

600

800

1000

Time

Time

FIGURE 38.3

PSD effect of coagulation with nano-IPF: growth of loc.

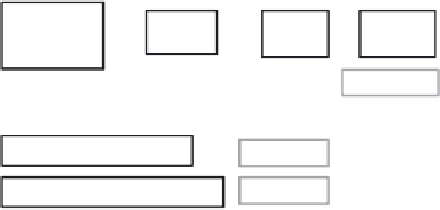

Production of high-Al

13

nano-IPF

Gibbsite

Al(OH)

3

gel

Ca(AlO

2

)

2

HCl

T

º

C, P

Spray

dried

Powder

product

Al

13

> 45%

Al

13

> 80%

Lab. microtitration

Nano-tech

material

Electrochemical

Al

13

> 80%

Al

13

> 80%

Membrane technology

Al

13

> 90%

Chem. separation

FIGURE 38.4

Schematic description of the industrialization of nano-IPF. SKLEAC, State Key Laboratory of Electroanalytical

Chemistry.

The current industrial production through high-temperature/high-pressure dissolution-

second alkaliication process can yield only <45% Al

13

. On the other hand, in laboratory

microtitration, it is easy to reach as high as 80% Al

13

. For an industrial-scale production,

the possible ways to reach high yields include electrochemical preparation, membrane

technology, and chemical separation and puriication. Figure 38.5 shows a demo-plant

established in Beijing, China, using the electrochemical preparation method.

The separation and puriication of Al

13

in PACl with various concentrations (0.05-0.5

mol/L) using the ultrailtration (UF) method have also been investigated (Huang et al.,

2006b). The relation between the species distribution data obtained by the ferron assay and

the interception data of UF membranes with different molecular weight cutoffs (MWCOs),

in which the concentration factor is neglected, is presented in Figure 38.6.

It can be clearly discovered that if the content of Al

b

rises in PACl, the fraction with

an MWCO >6 kilodaltons (kD) does not augment obviously, the 3-6 kD MWCO fraction