Environmental Engineering Reference

In-Depth Information

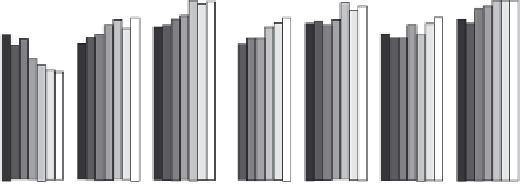

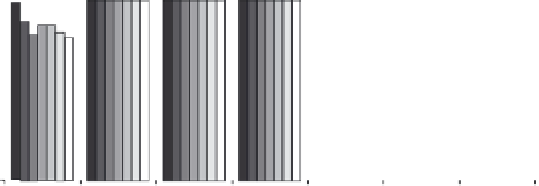

(a)

(b)

100

100

80

80

60

60

40

40

Sand

Sand

20

20

0

0

No Osorb

Fe-Osorb

(1%)

Fe-Osorb

(2%)

Mg-Osorb

(1%)

Mg-Osorb

(2%)

Zn-Osorb

(1%)

Zn-Osorb

(2%)

No Osorb

Fe-Osorb

(1%)

Fe-Osorb

(2%)

Mg-Osorb

(1%)

Mg-Osorb

(2%)

Zn-Osorb

(1%)

Zn-Osorb

(2%)

100

100

80

80

60

60

40

40

Soil mix

Soil mix

20

20

0

0

No Osorb

Fe-Osorb

(1%)

Fe-Osorb

(2%)

Mg-Osorb

(1%)

Mg-Osorb

(2%)

Zn-Osorb

(1%)

Zn-Osorb

(2%)

No Osorb

Fe-Osorb

(1%)

Fe-Osorb

(2%)

Mg-Osorb

(1%)

Mg-Osorb

(2%)

Zn-Osorb

(1%)

Zn-Osorb

(2%)

Simulated runoff events

Simulated runoff events

1st

2nd rd

4th

5th

6th7th

1st

2nd

3rd4th

5th th

7th

FIGURE 33.7

Removal eficiency of atrazine via unsaturated (a) and saturated (b) bioretention systems among three different Osorb-metal composites amendments (Fe-Osorb,

Mg-Osorb, and Zn-Osorb) with three different amounts (0%, 1%, and 2%) in two bioretention base media (sand and soil mix) from seven sequential runoff events.

Loading for each event was 0.5 mg of atrazine in 1 L (500 ppb).