Environmental Engineering Reference

In-Depth Information

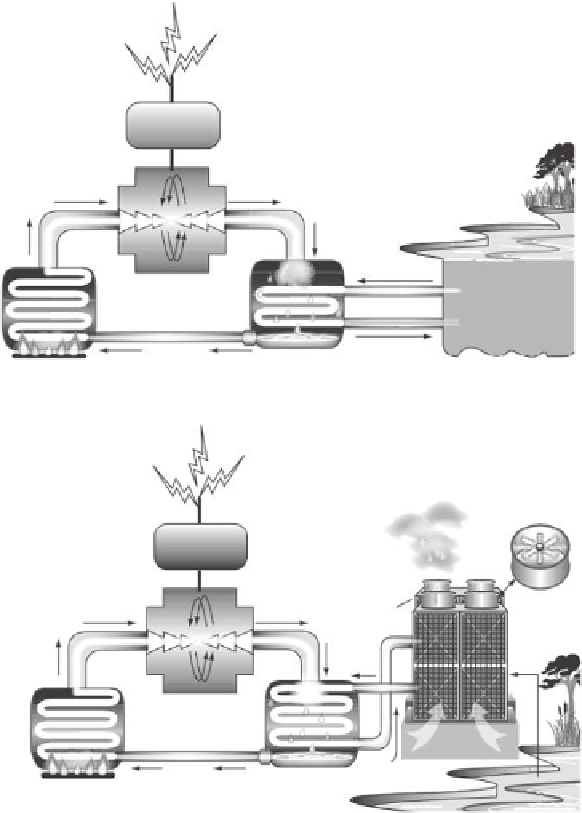

(a)

Electricity

Generator

Turbine

High-pressure steam

Low-pressure steam

Cool cooling water

intake from river

River

Boiler

Warm cooling

water discharge

back to river

Boiler water

Condenser

Heat source

(b)

Electricity

Fan

Generator

Evaporation

Low-

pressure

steam

Turbine

Cooling tower

Small

amount

of makeup

water

High-pressure steam

Cool

cooling

water

Boiler

Warm

cooling water

Ambient

air

Ambient

air

Boiler

water

Lake

Condenser

Heat source

FIGURE 28.7

Cooling schemes for thermoelectric power plants. (a) Once-through cooling scheme draws water from source,

which travels through a heat exchanger and then discharges the cooling water back to the source. (b) Similarly,

wet recirculating cooling draws water from a source and cools power plant working luid. The cooling water is

then allowed to cool, generally in a tower or pond, and then recirculated through the heat exchanger.

works by pulling water from a source, using it to cool the system in a single loop while

evaporating approximately 0.5%-1.6% of water withdrawn, typically between 100 and 400 gal/

MWh. Table 28.2 summarizes these values by plant type. The rest is discharged back to

the source at approximately 3°C higher than the inlet in the United States per regulations

[17]. The large amount of water needed for withdrawal to run a once-through cooled sys-

tem puts the plant at risk during times of water scarcity and can worsen an existing water

shortage [18]. In addition, concerns over water quality and availability, negative impacts

on aquatic life, increased water return temperatures, and highly invasive zebra mussels,

which foul intake structures, are also compelling economic reasons to improve thermo-

electric plant cooling systems [5,15] through innovative technology approaches. For exam-

ple, the Garimella group at Georgia Institute of Technology (Atlanta) has investigated the