Environmental Engineering Reference

In-Depth Information

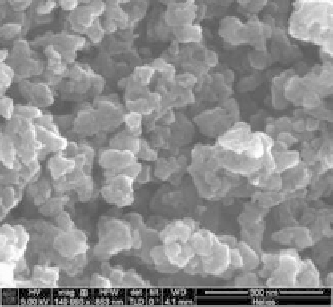

FIGURE 2.2

Scanning electron micrograph of the surface of carbon produced by carbonization of a resorcinol/formaldehyde

(R/F: 0.5) resin. Polymerization is catalyzed by CO

3

Na

2

(catalyst/R: 0.005) in water (water/R: 10) using a stabi-

lizer ([PDAMAC] = 0.0013 M). The resin is carbonized at 800°C in an Ar atmosphere.

depending on the iber size) but also stabilizes the micropores/mesopores likely by surface

tension effects [98].

In that way, a spontaneous hierarchical carbon material (bearing mac-

ropores and mesopores) could be produced (Scheme 2.4).

The holes in the cloth and space between microibrils give macropores to the material (Figure

2.3), while the stabilization of nanoparticles by the ibers gives nanopores to the material.

On the other hand, hydrophobic polymer ibers can be inserted inside the RF to produce

long macropores to produce hierarchical carbon [99], using PDAMAC as a stabilizer of

nanoporosity.

2.2.1.4 Use of Hard Template (Silica Nanoparticles) to

Produce Hierarchical Porous Carbon

Porous carbon can be obtained using templates of nanoscale sizes [100,101]. Hierarchical

porous carbon (HPC) [102-104] can be obtained using two templates in a somewhat complex

process. On the other hand, we have recently shown that the volume contraction of the car-

bon around a remaining hard template during pyrolysis induces the formation of additional

mesoporosity, and, besides the pores deined by the hard template, is able to create a hierar-

chical carbon material [105].

In that way, HPC can be obtained in a single pyrolysis step. Since

Macropores

Nanopores

Impregnation

with resin

Carbonization

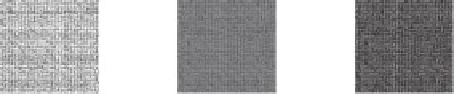

SCHEME 2.4

Synthesis of a hierarchical porous carbon (HPC-f) by carbonization of a cellulose cloth impregnated with RF

resin.