Environmental Engineering Reference

In-Depth Information

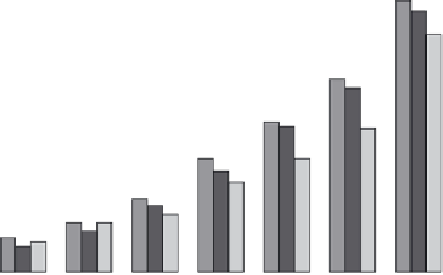

12

11

10

9

1% NaCl

3.5% NaCl

6% NaCl

8

7

6

5

4

3

2

1

0

15

23

31 40

Temperature difference (∆

T

)

45

51

60

FIGURE 23.12

Flux vs. cross membrane temperature difference for different NaCl concentrations. (From Feng, C. et al.,

Sep.

Purif. Technol.

, 102, 118, 2013.)

feed solution increases, the lux drops slightly, indicating a small change of water vapor

pressure with a change in NaCl concentration. The highest water lux achieved at the high-

est temperature difference (60°C) was 11-12 kg/m

2

h, which is comparable to the results

obtained for other research groups.

23.4 Current Status of the Nanofiber Filtering Media

Electrospun nanoibers are widely employed in iltration processes. The US company

Donaldson Co. (Minneapolis, MN)

63

produces electrospun iber-based ilter media (Ultra-

Web

®

) for applications in industry, consumer, and defense sectors. DuPont

64

adopts an

innovative new spinning process for fabricating high-eficiency, high-throughput “hybrid

membrane technology (HMT) nanoiber ilter media” (based on nylon 6) for superior liq-

uid iltration systems. The company claims unique attributes such as high iltration efi-

ciency, low ilter pressure drop, high low rate, and longer life. ELMARCO s.r.o. offers

industrial nanoiber production units (using the Nanospider

TM

machines).

65

The company

claims that low-cost nanoiber iltration media (deposited on an inexpensive substrate) not

only matches but also often exceeds the performance of the costly commercial iltration

media.

23.5 Future Trends and Limitations

There has been intense research in exploring the beneits of nanoibrous media in water

puriication in the past few decades. This trend is expected to grow as more insights about

the transport and behavior of nanoibers is achieved. Currently, there are a large number